What is the JM26 insulating firebrick

Mullite brick is also called mullite lightweight brick or mullite thermal insulation brick. Mullite thermal insulation brick is a high alumina refractory material with mullite (3Al2O3·2SiO2) mint a fő kristályfázis. Általában, között van a timföldtartalom 40% és 75%. In addition to mullite, the mineral composition contains a small amount of glass phase and cristobalite with a low alumina content, and a small amount of corundum with a high alumina content. JM26 mullite insulating firebrick is a kind of mullite brick.

Features of k26 insulating firebrick

As a refractory material with excellent performance, k23 insulating firebrick has a high melting point, high-temperature strength, low thermal expansion coefficient, kiváló hősokkállóság, stb., making it a refractory material in many industrial fields.

Three classification methods of mullite insulation bricks

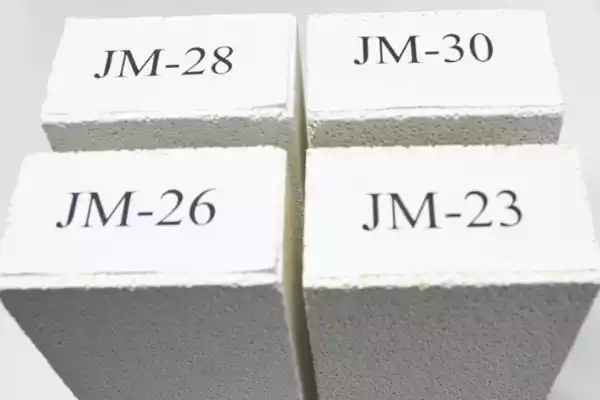

- Mullite insulation bricks are divided into JM23, JM26, JM28, and JM30 according to the grade.

- Mullite insulation bricks are divided into light mullite insulation bricks and corundum mullite insulation bricks (also known as heavy mullite insulation bricks) according to their density.

- Mullite thermal insulation bricks are divided into 1350 mullite thermal insulation bricks, 1450 mullite thermal insulation bricks, 1550 mullite thermal insulation bricks, stb. according to different operating temperatures, és 1550 mullite thermal insulation bricks can directly contact flames, and have high-temperature resistance and thermal conductivity. The coefficient is small, and the energy-saving effect is remarkable.

The raw material composition of mullite

Mullite insulation brick is a high-quality insulation brick made of high-quality high-alumina bauxite clinker as the main raw material, mixed with an appropriate amount of clay, ingredients, and water to make plastic mud or mud, extruded and fired at high-temperature Thermal insulation bricks.

Insulating firebrick JM26 application

- In the metallurgical industry, mullite can be used for hot blast stove bricks or kiln furniture bricks;

- In the glass industry, mullite can be used in structures such as glass containers, water feeders, and the top of glass kilns; in the field of ceramics, mullite can be used in high-temperature structural ceramics;

- In the gas industry, mullite can be used in oil gasification equipment, coke ovens, and gas generators in all gasification workshops.

- Mullite bricks can be used as the main component of the lining of furnace kilns, nagyolvasztó kemencék, and continuous casting furnaces

Rongsheng tűzálló anyagok gyára

Rongsheng tűzálló anyagok gyára

WeChat

Olvassa be a QR-kódot a wechat segítségével