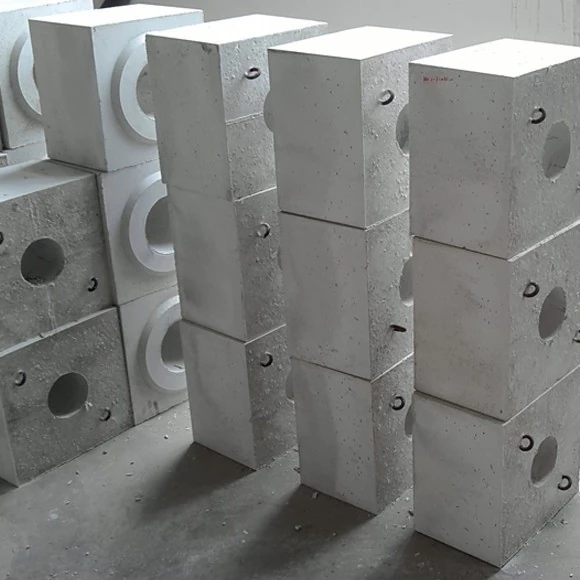

The ladle nozzle brick is made of high-purity raw materials, formed by vibration casting and low-temperature baking, and has the advantages of high thermal strength, thermal shock resistance, corrosion resistance and erosion resistance, and thermal repair.

Nozzle brick parameters

| Tétel | Index | ||

| Chromium Fused Alumina | Fused Alumina | Corundum Spinel | |

| Al2O3 % | ≥90 | ≥92 | ≥80 |

| Al2O3+MgO % | / | / | ≥92 |

| Kr2O3 % | ≥2 | / | / |

| Térfogatsűrűség g/cm3 | ≥3,0 | ≥2,95 | ≥2,95 |

| Hideg zúzószilárdság MPa | ≥60 | ≥50 | ≥50 |

| 0.2MPa Tűzállóság terhelés alatt ℃ | ≥1700 | ≥1700 | ≥1700 |

Features of nozzle bricks

- Magas tűzállóság,

- Magas hőmérsékleti ellenállás.

- Jó korrózióállóság.

- Good peeling and abrasion resistance.

- Jó hőütésállóság.

- High mechanical strength.

- Low creep rate at high temperature.

- Good volume stability at high temperatures.

The function of ladle nozzle brick

The ladle nozzle brick usually has a special shape to meet the needs of molten steel flow and pouring. When the molten steel flows out of the ladle, the ladle nozzle brick plays the role of diversion, buffer, and diversion, which plays a vital role in ensuring the smooth flow of molten steel and the quality of steel.

Rongsheng hot refractory material products

Rongsheng Company is a company specializing in the export of refractory materials. The company’s various refractory bricks are very popular, especially magas timföldtégla, magnézium-karbon tégla, magas króm tégla, korund téglák, és andalúz tégla. Ezen kívül, some insulation materials are often purchased by customers, such as ceramic fiber blankets, ceramic fiber boards, stb.

Rongsheng tűzálló anyagok gyára

Rongsheng tűzálló anyagok gyára

WeChat

Olvassa be a QR-kódot a wechat segítségével