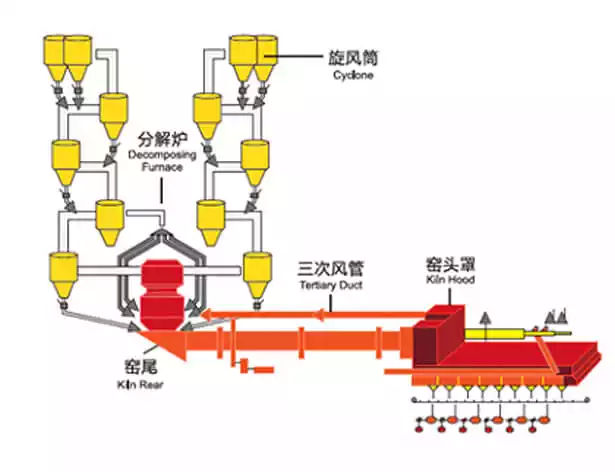

With new dry firing technology as the core, it realizes cement production automation and high efficiency and environmental protection, including a pre-decomposition system outside the kiln, rotary kiln system, and cooling system.

Cementipar

Refractories for the new dry-process cement rotary kiln:

Pre-Heater

High-strength alkali-resistant castable crust-resistant castable

Alkali-resistant bricks

Decomposing Furnace

High alumina low cement refractory CastableAnti-strip high alumina bricks

Tertiary Duct

Special castable for tertiary air duct

Silicon mullite bricks

High-strength alkali-resistant bricks

Rotary Kiln

Special castable for kilneyetabular

Corundum castable

Steel fiber reinforced refractory castable

Silicon mullite bricks

High-Wear resistant bricks

Magnesium iron spinel bricks

Direct bonded magnesia chrome bricks

Anti-strip high alumina bricks

Kiln Hood

Anti-strip high alumina bricks

Mullite low cement castable

Grate Cooler

Anti-strip high alumina bricks

Mullite low cement castable

Refractory bricks for the cement industry

There are many kinds of refractory bricks used in the cement industry: Direct-Bonded Magnesite chrome Bricks, Magnesite chrome bricks, Magnesia spinel bricks, Anti-strip alumina bricks, Silicon mullite bricks, Series alkali proof brick.

Direct-bond magnesite chrome bricks

Direct-bond magnesite chrome brick is a product made from fused magnesite and chrome concentrate sintered from high purity or secondary purity. It is sintered under high temperature and ultra temperature with fewer foreign materials, where the glass phase is centered in the triangular space, and the crystalline phase bonds directly with the crystalline phase. Featured by low porosity, nagy nyomószilárdság, strong wear resistance, good erosion resistance, and thermal shock resistance capacities as well as anti-strip properties, it applies to the calcining zone of dry-process cement rotary kiln.

| Elemek | DMC-4 | DMC-6 | DMC-9a | DMC-9b | DMC-12 |

| MgO% ≥ | 80 | 75 | 70 | 70 | 60 |

| Kr2O3 % ≥ | 4 | 6 | 9 | 9 | 12 |

| SiO2 % ≤ | 2.5 | 2.8 | 2.8 | 3.0 | 3.2 |

| Apparent Porosity % ≤ | 18 | 18 | 18 | 19 | 19 |

| MPa CCS ≥ | 40 | 40 | 40 | 40 | 35 |

| 0.2MPa Refractoriness Under Load ℃ ≥ | 1600 | 1600 | 1600 | 1580 | 1580 |

| Thermal Shock Resistance, Cycle (1100℃, water quenching) ≥ | 4 | 5 | 5 | 5 | 5 |

Magnesite chrome Brick

Magnesite chrome brick is a product sintered under a temperature above 1600℃ till as is the main material, and its host crystal phase is periclase and magnesia-chrome spinal. solidifying procedures or be packed with sheet steel externally. Featured by good thermal shock resistance, korrozióállóság, and anti-strip properties, it applies to the calcining zone of dry-process cement rotary kin.

| Elemek | Magnesia-chrome brick | |||

| MGe-8 | MGe-12 | MGe-16 | MGe-20 | |

| MgO % ≥ | 60 | 55 | 45 | 40 |

| Kr2O3,% ≥ | 8 | 12 | 16 | 20 |

| Látszólagos porozitás % ≤ | 21 | 21 | 21 | 21 |

| CCS ,MPa ≥ | 30 | 30 | 30 | 30 |

| 0.2MPa Refractoriness Under Load ℃≥ | 1530 | 1550 | 1550 | 1550 |

Magnesia Spinel Brick

| Tétel | MLJ-70 | MLJ-75 | MLJ-80 |

| MgO % ≥ | 70 | 75 | 75 |

| Al2O3 % | 8-13 | 8-13 | 8-13 |

| Fe2O3 % ≤ | 1.5 | 1.5 | 1.5 |

| CaO % ≤ | 2.0 | 2.0 | 1.5 |

| SiO2 % ≤ | 3.0 | 2.0 | 1.5 |

| Apparent Porosity %≤ | 19 | 18 | 17 |

| Bulk Density g/cm3 ≥ | 2.95 | 2.95 | 3.00 |

| MPa CCS ≥ | 45 | 45 | 50 |

| 0.2MPa Refractoriness Under Load ℃ ≥ | 1600 | 1650 | 1650 |

| Thermal Shock Resistance, Cycle (1100℃, water quenching) | 8 | 10 | 10 |

Anti-striping alumina brick and silicon mullite brick

The anti-striping alumina brick produced by our company is produced with special bauxite chamotte by adding aragonite or ZrO2 and molding under high pressure according to a certain proportion. Featured by strong anti-strip capacity, calcium, sodium, sulfur dioxide, chlorine and basic salt resistance, és alacsony hővezető képességgel, it is an ideal material for the transition zone and decomposing zone of cement kiln.

The silicon mullite brick produced by our company is produced with special bauxite chamotte by molding under high pressure and sintering under high temperatures. Featured by high ambient compressive strength and high structural strength. With good thermal shock resistance and wear resistance as well as strong anti-strip, it is an ideal material for the transition zone and decomposing zone of cement kin. cement kiln.

| Elemek | Anti-strip High Alumina Brick | Szilikon mullit tégla | |

| RSBR-70 | AZM-1650 | AZM-1680 | |

| Al2O3 % ≥ | 70 | 63 | 60 |

| ZrO2% | 6-8 | — | — |

| Thermal Shock Resistance, Cycle (1100℃, water quenching) ≥ | 1790 | 1790 | 1790 |

| Testsűrűség, g/cm3 ≥ | 2.5 | 2.55 | 2.60 |

| Látszólagos porozitás,% | 24 | 20 | 21 |

| CCS MPa ≥ | 60 | 65 | 70 |

| 0.2MPa Refractoriness Under Load ℃ ≥ | 1700 | 1650 | 1680 |

| CC CWT ≤ | – | 6 | 5 |

| Thermal Shock Resistance, Cycle (1100℃, water quenching) ≥ | 30 | 20 | 25 |

| MPa MOR ≥ | – | 12 | 15 |

Rongsheng tűzálló anyagok gyára

Rongsheng tűzálló anyagok gyára

WeChat

Olvassa be a QR-kódot a wechat segítségével