Five factors affecting the quality of high temp castable refractory

The quality of high temp castable refractory is affected by many factors, such as the composition and particle size distribution of refractory aggregates and fine powders; the amount of admixtures added; the mixing time of water addition; the sintering temperature, and other factors. These factors together determine the quality and performance of the castables.

1. Factors affecting the apparent porosity of refractory castables

There are three main types of pores in high-temperature castable refractory. The first is open pores, which are closed at one end and communicate with the outside world at the other end; the second is closed pores, which are enclosed in the material and do not communicate with the outside world; the third is through pores, which run through both sides of the material and allow fluid to pass freely. The apparent porosity is the percentage of the total volume of open pores in the sample to the total volume of the sample. There are many factors that affect the porosity of refractory castables, such as particle size and grading, water absorption: the amount of dispersant and binder added and their properties, mixing process, water addition, and vibration time. However, factors such as particle size distribution, vibration time, and binding system have a relatively large impact.

2. Factors affecting the room temperature strength of refractory castables

The normal temperature strength of refractory castables is mainly divided into two types: normal temperature flexural strength and normal temperature compressive strength. There are many factors that can affect these two strengths, such as the size and gradation of refractory particles, the size of grains, the type and amount of binder, etc., all play a vital role. Among them, the type and amount of binding agent have the most significant impact on these two strengths.

3. Factors affecting the high-temperature strength of refractory castables

The strength of refractory castables at room temperature and high temperature is a key indicator to measure the quality of their performance. This refractory material mainly serves high-temperature kilns and thermal metallurgical equipment to ensure the long-term stable operation of the furnace structure and equipment under a high-temperature environment. Among them, the high-temperature strength of refractory castables, especially the high-temperature flexural strength, is particularly important.

Refractory castables need to show excellent strength at all temperatures. It needs to be strong and stable at room temperature, while at high temperature, its strength is particularly important. And high-temperature flexural strength is an important criterion for measuring the performance of refractory castables at high temperatures.

The high-temperature flexural strength of refractory castables depends on two major factors: the crystallization effect and the glass effect. The crystallization effect determines the bonding and contact mode between crystals, providing a solid foundation for strength. The glass effect, its viscosity, and quantity determine the stability of the overall structure. The synergistic effect of these two effects enables refractory castables to maintain high strength at high temperatures, providing reliable protection for various harsh working environments. The high-temperature flexural strength of refractory castables is closely related to its practicality and is one of the important indicators for testing the performance of refractory castables. Its strength is determined by factors such as the firing temperature of the material, raw material composition, production process, chemical composition, impurity content, and organizational structure.

4. Factors affecting thermal shock resistance of high temp castable refractory

The thermal shock resistance of refractory castables is the performance of not being damaged when the temperature changes sharply. In practical applications, refractory castables often face large fluctuations in temperature, which is undoubtedly a severe test. The rapid change in temperature will produce thermal stress inside it. Once the thermal stress accumulates to a certain extent, it may cause cracks, peeling, and even overall damage. There are many factors that affect the thermal shock resistance of refractory castables, including the chemical composition of the castable itself, bond strength, external temperature fluctuations, crystal transformation, crystal structure, and the compactness of the internal structure. At the same time, its bonding system and matrix composition are also influencing factors that cannot be ignored.

5. Factors affecting the slag resistance of refractory castables

Slag damages and corrodes refractory castables through physical and chemical effects such as scouring, dissolution, and penetration of the melt. In order to verify its slag resistance, we used the static slag resistance crucible method for testing.

The erosion of the sample by the slag is mainly manifested in surface dissolution and penetration into the castable. This penetration not only expands the depth and area of the reaction but also causes the composition and structure near the surface of the sample to undergo qualitative changes, forming a metamorphic layer with high solubility. This accelerates the destruction process of the sample. Therefore, under the condition of the same material, the key factor that determines the slag resistance of the material is the microstructure of the matrix.

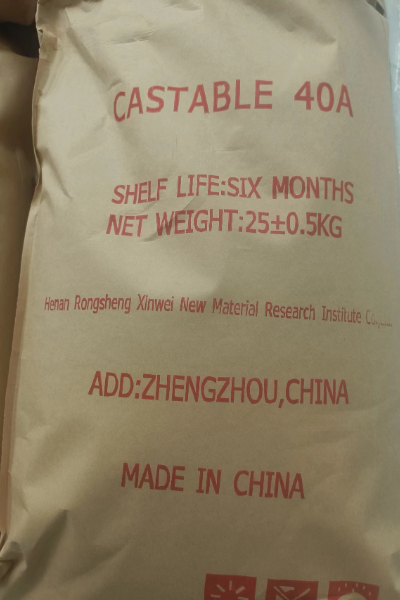

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Scan the QR Code with wechat