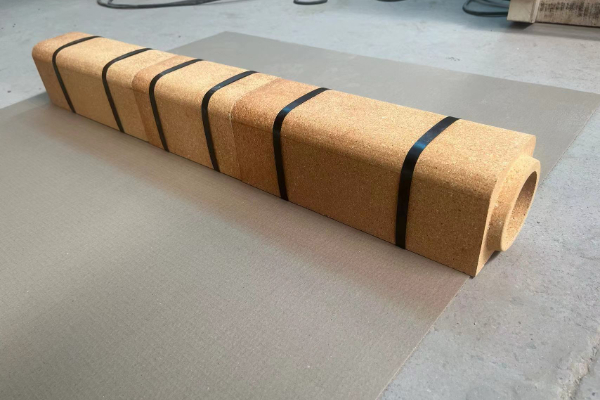

High Alumina Runner Bricks Exported to the South African Steel Industry

In August 2023, we exported a batch of high alumina runner bricks to South Africa. The South African customer is a large steel production company. The quality of the refractory bricks produced by Rongsheng is guaranteed and has good after-sales service. This is the very reason why customers choose us. important reason.

Introduction to flow steel bricks in the steel industry

Fluid steel bricks refer to hollow refractory bricks built in the groove of the ingot bottom plate to connect the steel bricks and the steel ingot mold. They are commonly known as soup road bricks. They are generally rectangular hollow clay bricks with various specifications. Flow steel bricks have high requirements because they need to be in direct contact with high-temperature molten steel. They are generally made of high aluminum and corundum, so their refractory resistance is also high, generally not less than 1580°C. The actual operating temperature can sometimes reach 1630°C. above.

The influence of high alumina runner bricks on molten steel

The production process of tundish bricks must be extremely precise. This is because any quality issues can easily affect the steel it comes into contact with, thereby impacting the quality of the final product. Since they are refractory materials used in steelmaking, such as tundish bricks, when the molten steel flows from the ladle into the ingot mold, it must pass through the tundish brick. Due to the high temperature of the molten steel, it exerts a force on the tundish brick, leading to localized detachment of its structure. Additionally, the molten steel interacts with the tundish brick and reaction by-products mix into the molten steel, affecting the quality of the ingot.

Successfully cooperated with South African customers

- Demand assessment and customized solutions: Customers contact us to seek high-performance high alumina runner bricks to replace traditional materials to improve production efficiency and ensure equipment safety. After understanding the customer’s specific needs, our engineering team provides a customized solution, including brick specifications, fire resistance, etc.

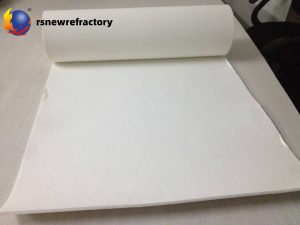

- Product supply and delivery: Our factory adopts advanced production technology to ensure stable product quality. We then arranged on-time shipping to ensure the products were delivered to the customer’s factory on time.

- Installation and technical support: We provide professional technical engineers to explain to customers the precautions and methods for using high alumina runner bricks to ensure successful application by South African customers

- Quality monitoring and after-sales service: We maintain close contact with our customers, conduct regular product quality inspections, and provide ongoing technical support. Our after-sales team is always ready to solve any problems that customers may encounter to ensure that their production lines can run stably and efficiently.

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Scan the QR Code with wechat