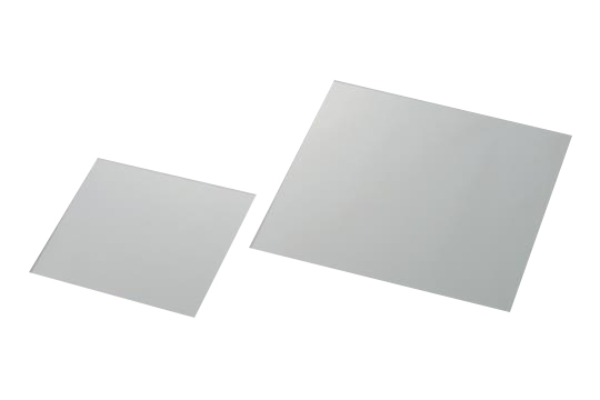

Fused Silica Plate Exported to Brazil

Rongsheng Refractory Co., Ltd. successfully completed the production of a batch of high-quality fused silica plate and successfully shipped them to customers in Brazil. Below are some details of our cooperation.

How can we get in touch?

We are a company that makes refractory materials. Our Brazilian customer is a chemical company. They need to purchase a batch of fused silica plates as linings for chemical equipment. The Brazilian customer saw our website and contacted us through online chat.

What kind of fused silica plate do customers need?

- Corrosion resistance: Fused quartz plates need to have excellent chemical corrosion resistance and be able to withstand erosion in various acid and alkali environments for a long time.

- High strength: Customers require fused quartz plates to have excellent mechanical strength and be able to maintain stability and integrity under harsh working conditions.

- Dimensional accuracy: The dimensions of the fused quartz plates need to strictly follow the design standards to ensure seamless splicing during the installation of the equipment lining and avoid safety hazards during equipment operation.

- Environmental protection requirements: The fused quartz plate material needs to comply with international environmental protection standards to ensure that no harmful substances are released during use to protect the safety of workers and the environment.

How do we collaborate?

Determine the indicators of fused quartz plate

After receiving the customer’s order, our sales manager immediately contacted the customer to determine the quantity, size, physical and chemical indicators, and other details of the fused quartz plate. After confirming the customer’s needs, the factory produced according to the Brazilian customer’s needs. Rongsheng Refractory Factory supports product customization, you only need to send your needs.

Factory customized production

In order to ensure product quality, we strictly control every link from raw material screening to finished product testing. During the production process, we communicate with customers many times to confirm product specifications and quality requirements to ensure that the products fully meet customer needs.

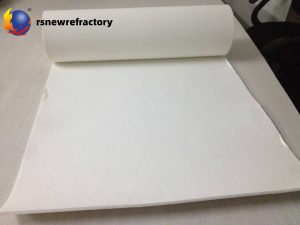

Fused silica plates ready to ship

After material preparation, batching, molding, sintering, and finishing, all fused quartz plates have passed strict quality inspections to ensure that each plate meets the high standards of customers. In the packaging process, we use professional protective measures to ensure that the fused quartz plates will not be damaged during long-distance transportation. All products are neatly stacked on sturdy wooden pallets, fixed and protected with shockproof materials, and finally loaded into containers ready to be shipped to Brazil.

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Scan the QR Code with wechat