Que sont les électrodes de four ?

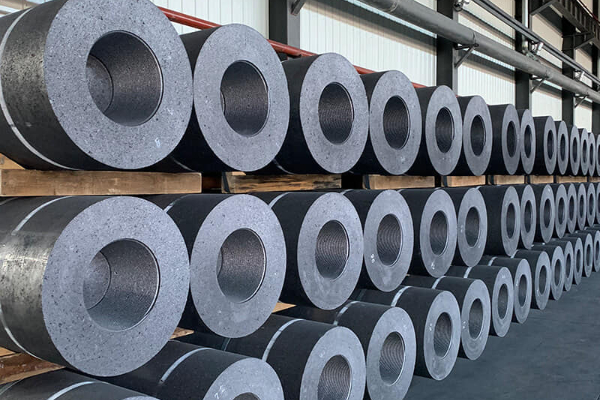

Furnace electrodes are électrodes de graphite. Les électrodes en graphite sont des matériaux conducteurs en graphite résistant aux hautes températures et constituent des consommables importants dans les industries de la sidérurgie et de la fabrication du silicium..

Classification des électrodes de graphite

According to the difference in power and current during use, it is produced using different raw materials and production processes. It can be divided into general power graphite electrode (RP), high power graphite electrode (HP), and Ultrahigh power graphite electrode (UHP).

Application of graphite electrodes

Ordinary power graphite electrodes are allowed to use graphite electrodes with a current density lower than 17A/cm2, which are mainly used in ordinary power electric furnaces for steelmaking, silicon refining, yellow phosphorus refining, etc.; high-power graphite electrodes are allowed to use graphite electrodes with a current density of 18~25A/cm2 Graphite electrodes are mainly used in high-power electric arc furnaces for steelmaking; ultra-high-power graphite electrodes allow the use of graphite electrodes with current densities greater than 25 A/cm2 and are mainly used in ultra-high-power electric arc furnaces for steelmaking.

What raw materials are needed to produce furnace electrodes?

A small amount of pitch coke can be added to ordinary power graphite electrodes, and the sulfur content of both petroleum coke and pitch coke cannot exceed 0.5%. Needle coke is also required when producing high-power or ultra-high-power graphite electrodes. The main raw material for aluminum anode production is petroleum coke, and the sulfur content is controlled to not exceed 1.5% à 2%.

How furnace electrodes are produced?

The process flow generally goes through 8 main processes, including calcination, ingredient mixing, pressing, roasting, impregnation, secondary roasting, graphitisation, and processing, to reach the finished product. The preparation cycle of graphite electrodes is 90-120 jours, of which the preparation cycle of graphite electrodes is 90 jours, and the production cycle of graphite electrode joints is about 120 jours.

Usine de réfractaires de Rongsheng

Usine de réfractaires de Rongsheng

WeChat

Scannez le code QR avec wechat