Rongsheng peut fournir une brique de feu à sk argile, qui peut être divisé en sk32, SK34, SK36, SK38, et les briques réfractaires SK40 selon la marque. Les briques réfractaires sont principalement utilisées pour la doublure du fournaise, cheminée, cheminée, et d'autres pièces. Les briques réfractaires produites par notre usine sont résistantes à l'usure, résistant à la corrosion, anti-flocation, fluage bas, bonne stabilité aux chocs thermiques, Et la vie de service est 1.5 fois celui des produits ordinaires; Ils sont principalement utilisés dans les hauts fourneaux, hauts fourneaux à chaud, fours de grillage au carbone, fours de calcination en carbone, fours à coke, louche en acier, système de coulée, chaudières, fours à ciment, fours en verre et diverses doublures du four et équipements thermiques, etc., adapté à la métallurgie, machinerie, matériaux de construction, fonderie, céramique, électricité, pétrole, industrie chimique et autres industries.

| Article | SK-30 | SK-32 | SK-34 | SK-35 | SK-36 | SK-37 | SK-38 | SK-40 |

| AL203 % (≥) | 30 | 35 | 38 | 45 | 55 | 65 | 70 | 82 |

| Fe203 % (≤) | 2.5 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Température de ramollissement sous charge, 0.2MPa, C (>) | 1250 | 1350 | 1370 | 1420 | 1450 | 1480 | 1530 | 1600 |

| Porosité(%) | 22-26 | 20-24 | 20-22 | 18-20 | 20-23 | 20-23 | 20-22 | 18-20 |

| Densité (g/cm³) | 1.9-2.0 | 1.95-2.1 | 2.1-2.2 | 2.15-2.22 | 2.25-24 | 2.3-2.5 | 2.4-2.6 | 2.5-2.7 |

| Résistance à la compression de température normale, MPa (≥) | 20 | 25 | 30 | 40 | 45 | 50 | 60 | 70 |

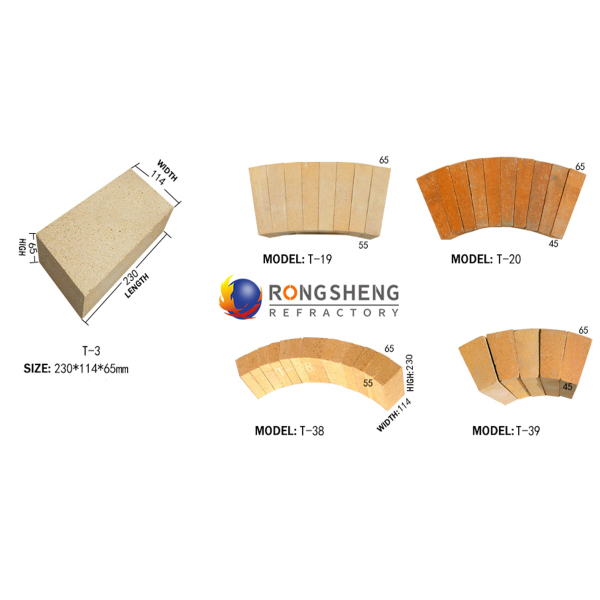

Tailles de briques d'incendie à l'argile SK

Les briques réfractaires en argile Sk ont des tailles de briques standard de 230*110*25 mm, et diverses briques réfractaires de forme spéciale, y compris les briques incurvées, Briques en acier à flux, etc., qui peut également être personnalisé en fonction de vos dessins.

Caractéristiques des briques d'argile SK

- Excellente résistance à la corrosion et résistance à l'usure;

- Bonne résistance aux chocs thermiques;

- Bonne résistance à la corrosion anti-dépouillement et à la corrosion chimique;

- Avantage des prix par rapport aux briques élevées en alumine

- Excellentes performances thermiques et résistance à l'acide;

- Bonne stabilité dimensionnelle à haute température;

- Haute résistance mécanique;

Processus de production de la brique Clay Sk

Les principales matières premières pour fabriquer des briques d'argile légères sont des agrégats d'argile légers et de la poudre d'argile, Et le matériau brûlé est de la sciure. Les matières premières sont broyées et pulvérisées avant d'être mélangées dans un mélangeur. L'ordre d'ajout de matériaux: Ajoutez d'abord des agrégats légers et de l'argile, Mélanger à sec pour 2 minutes, puis ajouter de l'eau, mélange humide pour 6 minutes, puis décharger. La teneur en humidité de la boue est de 17 à 20%.

Une fois la boue piégée pour 24 heures, Il est formé par une presse à brique de friction. Les briques sont séchées dans un séchoir à tunnel et tirées dans un four de lignes descendante. La température de tir élevée est de 1250 ℃, Et il est maintenu au chaud pour 4 heures. Il peut être déchargé du four après un refroidissement naturel pour 24 heures.

Utilisations des briques réfractaires SK

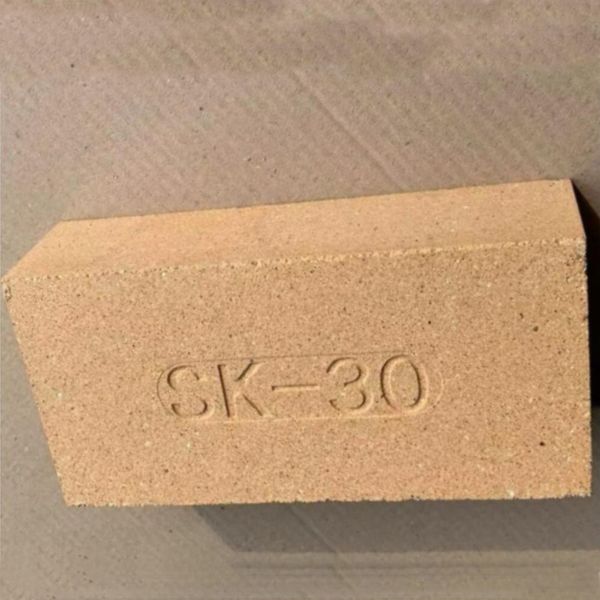

Sk30 Fire Clay Bricks

Les briques SK30 sont principalement utilisées pour la doublure des fours de chauffage général, fours rotatifs, chaudières, fours ordinaires, et autres fours industriels avec de faibles températures de travail. La réfractarité des briques SK30 est relativement faible et convient aux occasions avec des exigences à basse température.

Sk32 Fire Clay Bricks

Les briques SK32 sont utilisées pour les revêtements de fournaises qui nécessitent des températures légèrement plus élevées, comme les fours en verre, fours en céramique, fours à chaux, etc.. Les briques SK32 ont une réfractarité légèrement plus élevée que SK30 et conviennent aux applications à température moyenne.

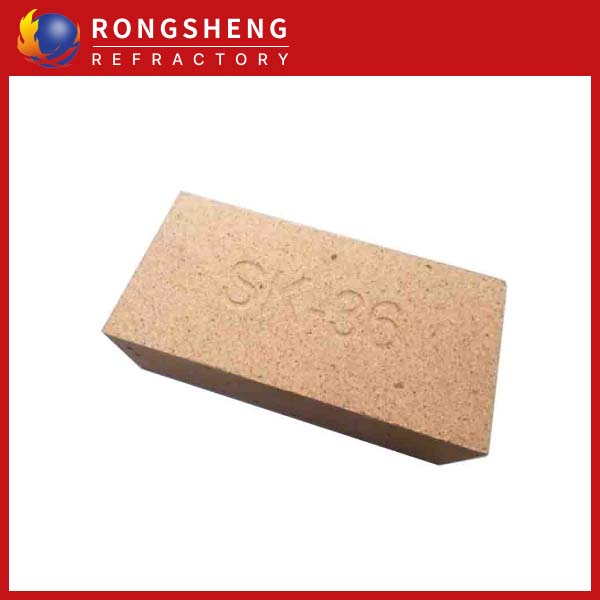

Sk34 Clay Fire Bricks

Les briques SK34 sont utilisées dans des fours à haute température tels que les fours à base d'acier, Fours en alliage en aluminium, et les fours de traitement thermique dans le pétrochimique (chaudière) industrie. Ils conviennent à une utilisation à des températures plus élevées et ont une bonne résistance à la corrosion chimique.

Sk36 Briques d'argile réfractaires

Les briques SK36 sont largement utilisées dans des équipements à haute température tels que les hauts fourneaux, hauts fourneaux à chaud, et fours de frittage en acier (haut fourneau, four électrique, louche), pétrochimique, verre, ciment, et d'autres industries. Ils ont une résistance aux chocs thermiques et une réfractarité élevées et conviennent à une utilisation à des températures plus élevées et des environnements chimiques complexes.

Briques résistantes au feu SK38

Les briques SK38 sont utilisées pour les doublures à des températures extrêmement élevées et des environnements durs, comme les fours à arc électrique, calcineurs à haute température, et d'autres équipements spécialisés à haute température. Les briques SK38 ont la résistance au feu et la résistance chimique la plus élevée, Les rendre adaptés aux processus nécessitant des températures extrêmement élevées et des conditions extrêmes.

Notre usine de briques réfractaires

Nos clients visitent

Usine de réfractaires de Rongsheng

Usine de réfractaires de Rongsheng

WeChat

Scannez le code QR avec wechat