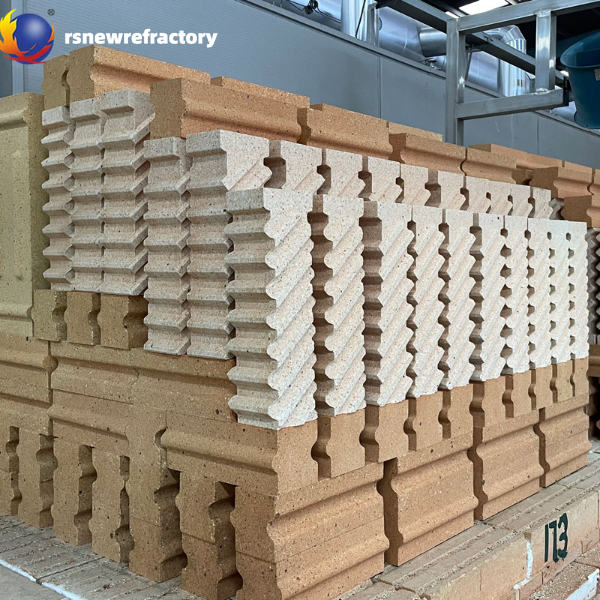

Classification des briques réfractaires d'ancrage

Les briques réfractaires d'ancrage sont un matériau spécial largement utilisé dans les fours industriels à haute température pour soutenir et fixer la structure du revêtement réfractaire.. Grâce à sa conception unique, briques d'ancrage peut améliorer efficacement la résistance et la stabilité de la doublure réfractaire et prolonger la durée de vie de l'équipement. Cet article introduira en détail la classification des briques d'ancrage réfractaires et leurs applications spécifiques dans l'industrie.

Classification des briques réfractaires d'ancrage

Brique d'ancrage à haute alumine

Matières premières: La bauxite à haute alumine est la principale matière première, Et le contenu en alumine est généralement au-dessus 48%.

Caractéristiques: Il a une bonne résistance à haute température et une résistance à la corrosion, et est largement utilisé dans l'industrie sidérurgique et les fours à ciment.

Application: Utilisé dans les zones où une résistance à haute résistance et à l'usure est nécessaire dans les fours à haute température.

Briques d'ancrage d'argile

Matières premières: L'argile réfractaire est la principale matière première, avec un contenu en alumine relativement faible.

Caractéristiques: Performances à coût élevé, Convient pour les fours à température moyenne ou les zones de charge basse.

Application: Appliqué à la fixation de doublure des fours de petite et moyenne taille.

Brique d'ancrage en corundum

Matières premières: Corundum fusionné ou corindum fritté comme principaux matières premières, avec un contenu en alumine de plus que 90%.

Caractéristiques: Résistance à la corrosion extrêmement forte et résistance à l'usure, Excellente résistance à la température.

Application: Utilisé dans les fours industriels à haute température qui nécessitent une résistance à une température extrêmement élevée et une résistance à la corrosion.

Brique d'ancrage en carbure de silicium

Matières premières: Le carbure de silicium est le composant principal, généralement avec un liant ajouté.

Caractéristiques: forte résistance à l'usure, Excellente conductivité thermique, excellente résistance aux chocs thermiques.

Application: Adapté aux zones de refroidissement des fours à haute température et des zones qui nécessitent une dissipation de chaleur rapide.

Champs d'application des briques d'ancrage réfractaires

Industrie sidérurgique

Appliqué pour réparer la doublure réfractaire des hauts fourneaux, fours à arc électrique, et convertisseurs, et résister à l'érosion du métal fondu à haute température et des scories.

Industrie du ciment

Utilisé dans les fours rotatifs en ciment, fours de décomposition,s, et d'autres pièces pour réparer les moulages réfractaires et les briques réfractaires.

Industrie du verre

Utilisé dans la chambre de rangement de chaleur et le toit du four de four en verre pour soutenir la structure du four et résister à l'érosion des gaz à haute température.

Industrie pétrochimique

Utilisé dans des dispositifs à haute température tels que les fours de fissuration et les fours à gazéification pour réparer les moulages réfractaires et les couches d'isolation.

Autres domaines

Y compris des équipements de four à haute température tels que les fours en céramique, incinérateurs de déchets, et fours industriels en aluminium.

Usine de réfractaires de Rongsheng

Usine de réfractaires de Rongsheng

WeChat

Scannez le code QR avec wechat