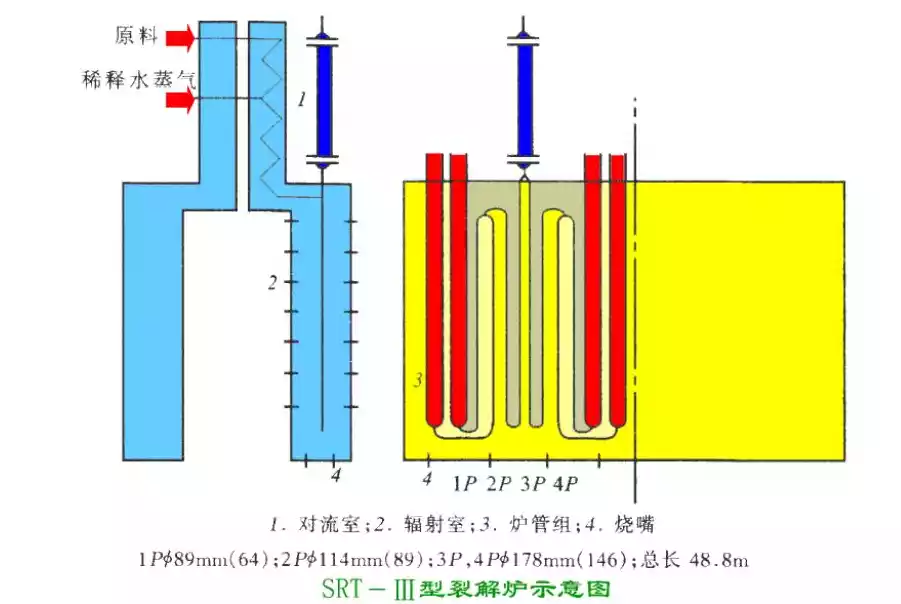

Le four de craquage est au cœur de la production d'éthylène, et le matériau réfractaire est un facteur important affectant la durée de vie du four de craquage. Parmi eux, le revêtement et le groupe de travail du four de craquage SRT utilisent des matériaux réfractaires.

Four de craquage SRT

Réfractaires pour four de craquage SRT

Dans la zone interne à haute température du four de craquage, des briques réfractaires sont utilisées pour construire le mur et le fond du four.

Bétons réfractaires:

Les bétons réfractaires sont utilisés pour combler et réparer les petits espaces et les parties endommagées des fours..

Utilisé pour la couche isolante du four.

Dans la zone externe du four de pyrolyse, les briques isolantes sont utilisées pour réduire la conduction thermique et les pertes de chaleur.

Revêtement barrière thermique:

Les surfaces externes du four de pyrolyse sont recouvertes d'un revêtement barrière thermique. Ces revêtements sont généralement constitués de fibres céramiques, ciment réfractaire et autres matériaux, ce qui peut fournir un meilleur effet d'isolation thermique.

Couverture en fibre céramique

| Température de classification ℃ | 1140 | 1260 | 1400 | ||

| Grade | XT114 | XT126-A | XT126-B | XT140-A | XT140-B |

| Changement linéaire permanent % ℃×24h | ≤-3 950 | ≤-3 1000 | ≤-3 1100 | ≤-3 1200 | ≤-3 1350 |

| Conductivité thermique W/(m·K)500℃ | ≤0,153 | ||||

| Résistance à la traction MPa 25 mm d'épaisseur | > 0,04 | > 0,05 | > 0,04 | > 0,06 | |

| Densité apparente kg/m3 | 64/96/128/160 | ||||

| Al2O3 % | ≥44 | ≥45 | ≥45 | ≥52 | ≥36 |

| SiO2 % | ≥52 | ≥52 | ≥54 | ≥46 | ≥48 |

| ZrO2 % | / | / | / | / | ≥15 |

| Fe2O3 % | ≤1.0 | ≤0.8 | ≤0.2 | ≤0.2 | ≤0.1 |

| Al2O3+SiO2 % | ≥96 | ≥97 | ≥99 | ≥99 | ≥ |

| Al2O3+SiO2+ZrO2 % | / | / | / | / | 99 |

| Taille | 3600/7200×610×20/30/50 | ||||

Plastique réfractaire

| Article | Carbure de silicium | Corindon Chrome Zirconium | ||

| NMK4 | NMK5 | NMK6 | NMK7 | |

| Al2O3 % | / | / | / | ≥80 |

| SiC % | ≥40 | ≥60 | ≥70 | / |

| Cr2O3 % | / | / | / | ≥3 |

| ZrO2 % | / | / | / | ≥2 |

| Densité apparente g/cm3 110℃×24h | ≥2,4 | ≥2.5 | ≥2,6 | ≥2,8 |

| Changement linéaire permanent % 1000℃×3h | -0.4~0 | -0.5~0 | -0.6~0 | -0.6~0 |

| Résistance à l'écrasement à froid MPa 1000℃×3h | ≥60 | ≥70 | ≥80 | ≥90 |

| Résistance à l'usure à température ambiante cm3 1000℃×3h | ≤7 | ≤6 | ≤5 | ≤5 |

| Cycle de stabilité aux chocs thermiques refroidissement par eau 1000 ℃ | ≥30 | ≥35 | ≥40 | ≥30 |

| Indice de plasticité % | 15~55 | |||

| Plasticité avec(m·K) 1000℃ | 3~5 | 5~7 | 6~8 | 2~3 |

| Température de service maximale ℃ | 1400 | 1500 | 1600 | 1600 |

Coulable réfractaire à haute teneur en alumine

| Indice | Moulable à haute teneur en alumine | |

| Al2o3% | 65 | |

| Sio2 % | 30 | |

| Ca % | 6 | |

| Densité apparente g/cm³ | 110℃,24h | 2.5 |

| 1350℃,24h | 2.6 | |

| Résistance à la flexion à froid MPA | 110℃,24h | 6 |

| 1350℃,24h | 7.5 | |

| Résistance à la flexion à chaud MPA | 110℃,24h | 45 |

| 1350℃,24h | 60 | |

| 1350 Taux de changement de la ligne brûlante | 0.2 | |

| Consommation d'eau de gâchage % | 10-12% | |

| Température de fonctionnement | 1400 | |

Usine de réfractaires de Rongsheng

Usine de réfractaires de Rongsheng

WeChat

Scannez le code QR avec wechat