sk34 bricks exported to Honduras

Kamakailan lamang, we successfully signed a contract with a large steel manufacturing company in Honduras to purchase SK34 bricks. This was our first cooperation with this customer. After several rounds of detailed communication and technical exchanges, the two sides finally reached a deal.

Honduras customer introduction

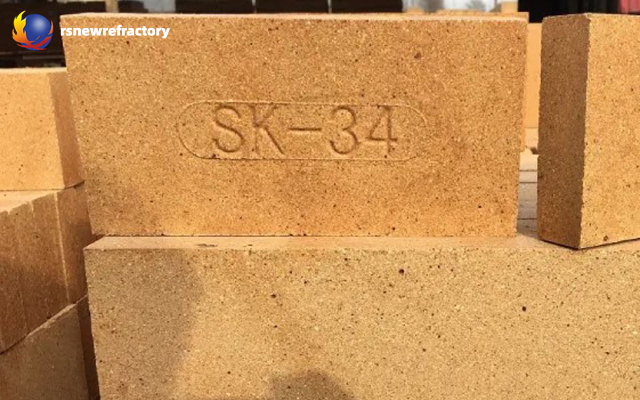

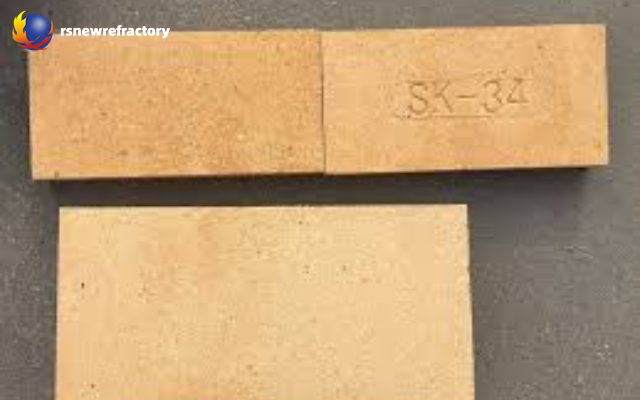

The customer is located in Honduras and is a well-known local steel production company, mainly engaged in steel smelting and processing. The customer recently needs a batch of sk34 refractory bricks, the quantity is 20,000 pieces, and the refractory brick size is the standard size of 230*114*65mm

About sk34 brick cooperation

After a preliminary understanding of the product performance, the customer asked us to provide more detailed technical information and raised some targeted questions, such as the stability of refractory bricks in high-temperature environments, the ability to resist slag erosion, atbp. According to the customer’s requirements, we further improved the samples and conducted relevant tests to ensure that their quality could meet the needs of the high-temperature smelting process.

After understanding the customer’s purchase volume and long-term cooperation intention, we proposed a competitive price and made appropriate adjustments based on the customer’s needs. After several rounds of communication and negotiation, the two parties reached an agreement and finally signed a long-term supply contract covering large quantities of SK34 brick purchase orders.

Advantages of SK34 bricks

Paglaban sa mataas na temperatura

SK34 bricks are made of high-bauxite ore as the main raw material. They have extremely strong high-temperature resistance and can withstand working temperatures of up to 1400℃-1500℃, which can meet the high-temperature requirements of Honduran customers during the steel smelting process.

Excellent thermal shock stability

Due to its excellent thermal shock resistance, SK34 bricks can effectively resist cracks caused by thermal expansion and contraction when the temperature in the furnace changes frequently, extending the service life of the furnace lining.

Strong acid and alkali resistance

During the smelting process, SK34 bricks can effectively resist the erosion of acidic and alkaline substances in steel smelting, ensure the stability of the furnace lining, and reduce maintenance costs.

Higher mechanical strength

SK34 bricks have high mechanical strength and can effectively withstand the impact and pressure generated during the smelting process, and are suitable for various high-load environments.

Successfully signed a contract

The cooperation with Honduras customers is a successful case, demonstrating the competitiveness of our refractory products in the international market and our service capabilities. If you are interested in our products, Mangyaring huwag mag atubiling makipag ugnay sa amin, we will provide you with professional consultation and high-quality product solutions.

Rongsheng Refractories Pabrika

Rongsheng Refractories Pabrika

WeChat

Scan ang QR Code sa wechat