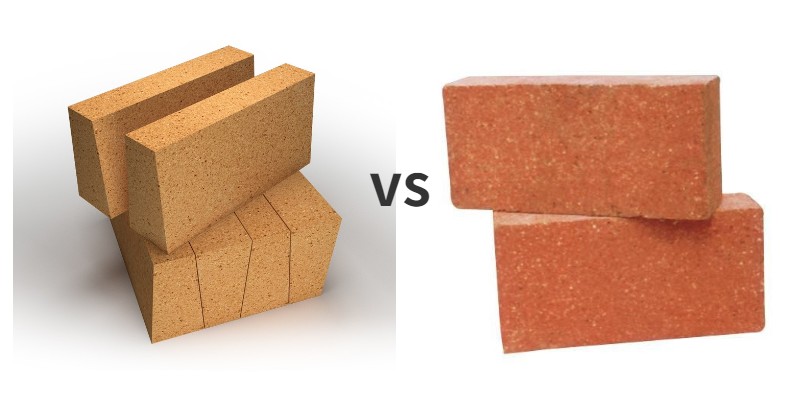

Comparison between refractory clay bricks and ordinary bricks

Refractory clay bricks are special bricks with excellent high-temperature resistance and are widely used in high-temperature industrial equipment. While ordinary bricks are usually a conventional building material for construction and interior decoration. The following is a description of their differences.

The difference between refractory clay bricks and ordinary clay bricks

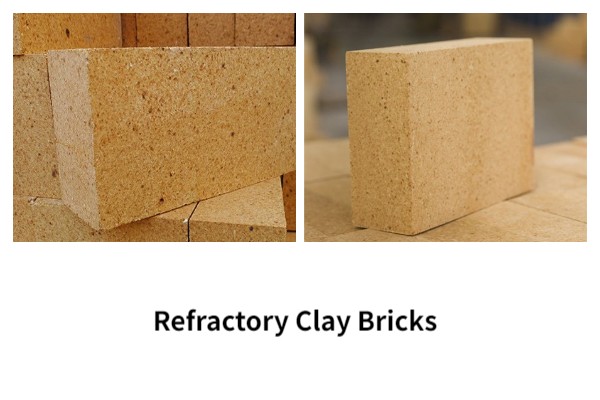

Ingredients are different

- Refractory clay brick: The main components are kaolin and other refractory materials, and the content of kaolin is relatively high, usually reaching more than 50%.

- Ordinary clay bricks: the main components are ordinary clay and other materials, and have no special fire resistance.

The use range is different

- Refractory clay bricks: suitable for refractory buildings such as high-temperature industrial furnaces, furnaces, stoves, chimneys, atbp., which can withstand high temperature and chemical corrosion environments.

- Ordinary clay bricks: suitable for general construction and decoration projects, such as house walls, ground paving, fences, atbp.

The production process is different

- Refractory clay bricks: high-quality refractory materials such as kaolin are used, and fired at high temperatures to ensure stable refractory performance.

- Ordinary clay brick: It is relatively simple to make, using ordinary clay and other auxiliary materials, and usually fired at a lower temperature.

Advantages and disadvantages of ordinary clay bricks and refractory clay bricks

Characteristics of refractory clay brick

Advantages: It has extremely high fire resistance, can be used for a long time in high-temperature environments, and has strong chemical corrosion resistance.

Disadvantages: high cost, complex manufacturing process, limited scope of application, and cannot be used at room temperature.

Ordinary clay brick

Advantages: The production process is simple, the cost is relatively low, the application range is wide, and it can be used at room temperature.

Disadvantages: no fire resistance, cannot be used in high temperature and fire resistant environment, easy to deform or break at a higher temperature

Refractory brick manufacturers

Rongsheng is a refractory manufacturer in Zhengzhou. We can provide different types of refractory materials. If you need, please leave your contact information.

Rongsheng Refractories Pabrika

Rongsheng Refractories Pabrika

WeChat

Scan ang QR Code sa wechat