Ano ang Mangyayari Sa Panahon ng Produksyon ng Alumina Refractory Bricks?

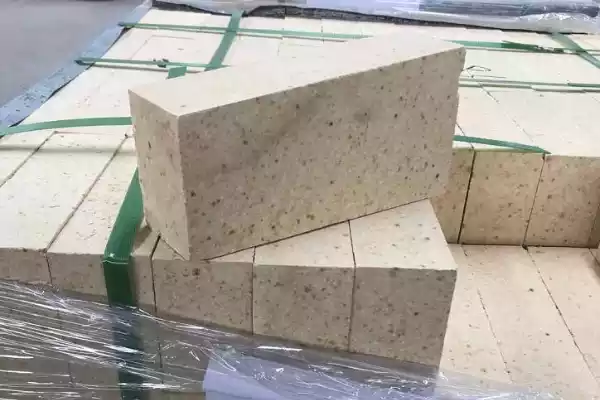

In the production process of aluminum refractory bricks, there will be some defective products. In addition, if the production technology of mga brick na refractory is not mastered, it will lead to bad phenomena in the batch output during the production process. The following are some common adverse phenomena in the production process of aluminum bricks and their causes.

What problems will arise in the production process of aluminum refractory bricks?

What happens when aluminum refractory bricks are underfired?

Underfiring is caused by insufficient firing temperature, insufficient holding time, or leakage of cold air. Under normal circumstances, under-fired high-alumina bricks have low mechanical strength, loose bonding, low sound when knocked, easy to be damaged when transported, and poor high-temperature performance and corrosion resistance.

What problems will occur when aluminum refractory bricks are overfired?

Overburning is a problem caused by the firing temperature being too high, the holding time is too long, or the flame directly contacting the brick surface. In general, overfired high alumina bricks have high mechanical strength, low apparent porosity, large size shrinkage, large brick body deformation, too tight combination, severe vitrification, rattling when knocked, and poor thermal shock resistance. However, when the raw materials contain high transition metal oxide impurities such as FeO and TiO, overfiring may also cause high-alumina bricks to foam, resulting in a decrease in density, an increase in apparent porosity, and an increase in volume expansion.

Why do aluminum bricks break?

Damage refers to defects such as missing edges, falling corners, and falling grains after burning. The reason may be that the amount of matrix is too small, the strength of the binder is insufficient, the force is too strong during transportation, uneven mixing, particle segregation, insufficient molding pressure or low firing temperature, atbp.

Deformation of aluminum refractory bricks

High alumina bricks are prone to shape changes or deformations at high temperatures. This may be caused by too high sintering temperature, too long sintering time, or uneven material. Deformation may affect the dimensional stability and installation quality of high alumina bricks.

Why do refractory bricks crack?

During sintering or cooling, cracks may appear due to internal temperature differences or thermal stress. This can lead to a reduction in the strength of the brick or even damage the integrity of the brick.

Rongsheng Refractories Pabrika

Rongsheng Refractories Pabrika

WeChat

Scan ang QR Code sa wechat