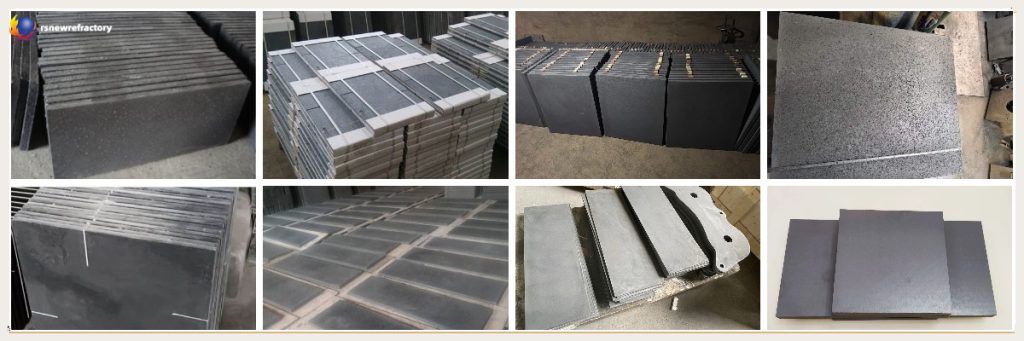

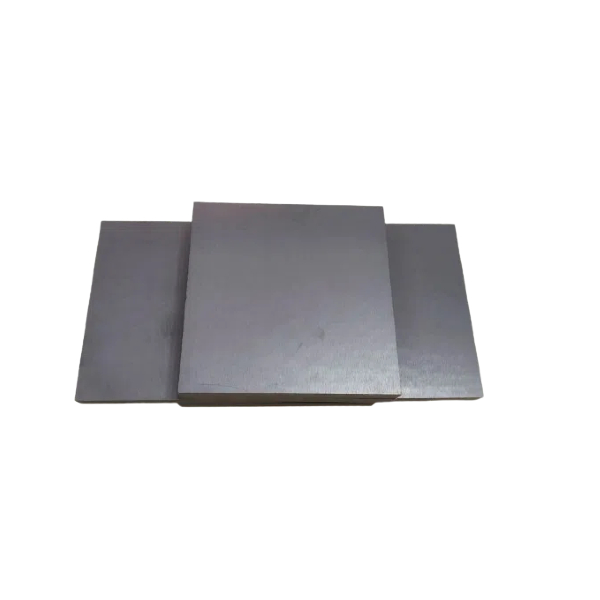

Oxide-bonded SiC refractory plate kiln furniture is made of high-quality silicon carbide as raw material, with vanadium pentoxide, barium carbonate, methylcellulose, and other binders added, high-pressure molding, and sintered at 1470℃. Oxide-bonded silicon carbide kiln furniture has a small expansion coefficient, good thermal conductivity, oxidation resistance, high-temperature resistance, paglaban sa kaagnasan, wear resistance, and long service life. It is widely used in various daily-use ceramics, sanitary ceramics, high-voltage electric ceramics, electronic ceramics, grinding wheels, magnetic materials, at iba pang mga industriya, suitable for tunnel kilns, shuttle kilns, roller kilns, push-plate kilns, atbp.

Features of silicon carbide plate

- Silicon carbide plates have a wide operating temperature range. The operating temperature range is about 800℃-1400℃;

- High thermal conductivity can save kiln performance;

- Extremely high thermal conductivity, good high-temperature erosion resistance, and excellent wear resistance.

- It has good thermal shock resistance and is not easy to break in the face of extremely cold and hot working environment changes;

- High density, makinis na ibabaw, no slag during use;

- Strong adaptability, can adapt to the oxidizing atmosphere and reducing atmosphere in ceramic production;

- SIC refractory kiln tools have high strength, long service life, and turnover times of about 500-1000 times.

Application of SiC refractory plate raw materials

Silicon karbid has four main application areas: functional na keramika, advanced refractory materials, abrasives, and metallurgical raw materials.

⑴ As an abrasive, it can be used to make grinding tools, such as grinding wheels, oilstones, grinding heads, sand tiles, atbp.

⑵ As a metallurgical deoxidizer and high-temperature resistant material.

⑶ High-purity single crystals can be used to manufacture semiconductors and silicon carbide fibers.

Application of silicon carbide plate

Ceramics industry

Silicon carbide plates have a wide range of applications in the ceramic industry. They are often used to produce grinding wheels, ceramic coatings such as enamels and electrical insulators, daily ceramics, architectural ceramics, and glass and papermaking processes, including nozzles, nozzles, kiln furniture, and cyclone separator components.

Metallurgical Industry

More than 65% of large blast furnaces in the world use silicon carbide materials, extending the life of blast furnaces by up to 40%. These materials are widely used as furnace linings or crucibles when smelting aluminum, copper, and zinc. In addition, silicon nitride plates can be used to manufacture immersion thermocouple tips for measuring the temperature of steel in electric furnaces. If you want to learn more cases, please visit KERUI Pinterest.

Industriya ng Kemikal

In the chemical industry, ceramic heat exchangers are often used to recover waste heat from various furnaces by preheating gases or liquids. Silicon carbide refractory plates can be used as efficient heat exchanger materials with their excellent thermal properties and high-temperature strength. Silicon carbide has a thermal conductivity three times higher than steel, making it an ideal material for manufacturing thermocouple protection tubes for temperature measurements up to 1400°C.

Energy Industry

Carborundum plates have a wide range of applications as environmental heat exchangers. High-temperature purified coal gas is directly used for gas turbine power generation, significantly improving power generation efficiency and reducing harmful emissions.

Filtration System

Silicon carbide plates play an important role in high-performance, high-temperature particle control ceramic filtration systems. These systems not only promote the use of advanced fossil fuels but also have great application potential in other high-temperature industrial processes, waste incineration, at iba pang larangan. Kerui Refractory Company will provide the best quality and service.

Rongsheng Refractories Pabrika

Rongsheng Refractories Pabrika

WeChat

Scan ang QR Code sa wechat