Semi-silica brick is an aluminum silicate refractory product with an alumina (Al2O3) content of 15-30%, and is a semi-acidic refractory brick. Semi-silica bricks generally use refractory clay containing quartz sand, pyrophyllite, refractory clay, or kaolin beneficiation tailings as raw materials. Semi-silica bricks shrink less during firing, because at 1250°C, the quartz in the raw material is converted into cristobalite, and the volume expands, which partially offsets the shrinkage produced during clay sintering. The manufacturing process of semi-silica bricks can be divided into two types: fired or not fired. The manufacturing process of fired bricks is basically the same as that of clay bricks; non-fired bricks are mostly made of water glass as a binder.

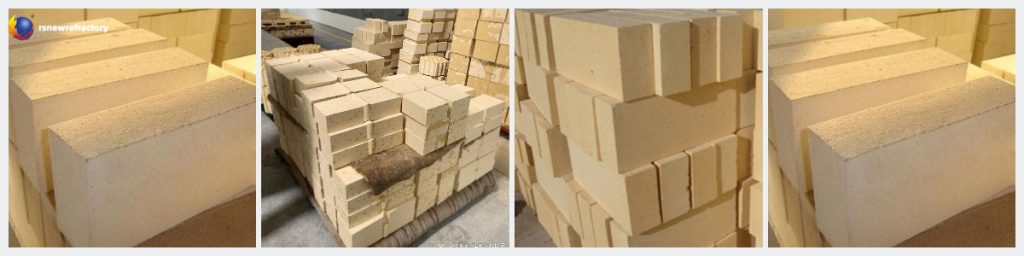

Semi-silica brick details

| Product Name | Semi-silicon brick |

| AI2O3/% | 21.59 |

| SiO2/% | 76.58 |

| Fe2O3/% | 0.83 |

| Refractoriness℃ | 1630-1650 |

| Bulk Density g/cm³ | 2.1 |

| Apparent Porosity % | 18 |

| Normal temperature compressive strength / MPa | 29 |

| Load softening temperature(T6.6) / °C | 1490 |

Characteristics of semi-silica bricks

Refractory: The refractoriness of semi-silica bricks is usually between 1580°C and 1680°C.

Paglaban sa kaagnasan ng kemikal: It has good corrosion resistance against acidic and alkaline slags.

Thermal stability: It has good thermal stability and is suitable for environments with large temperature fluctuations.

Semi-silica brick application

Semi-silica bricks are stable in volume at high temperatures (slightly expanded), which is beneficial to improving the integrity of the masonry and reducing the erosion of the slag on the masonry; when in contact with high-temperature slag, a layer of viscous glaze-like substance is formed on the surface of the brick, blocking the pores and preventing the slag from penetrating into the brick, thereby improving the brick’s anti-erosion ability; and the load-deformation temperature is relatively high; so in some occasions, its service life is not inferior to that of ordinary clay bricks.

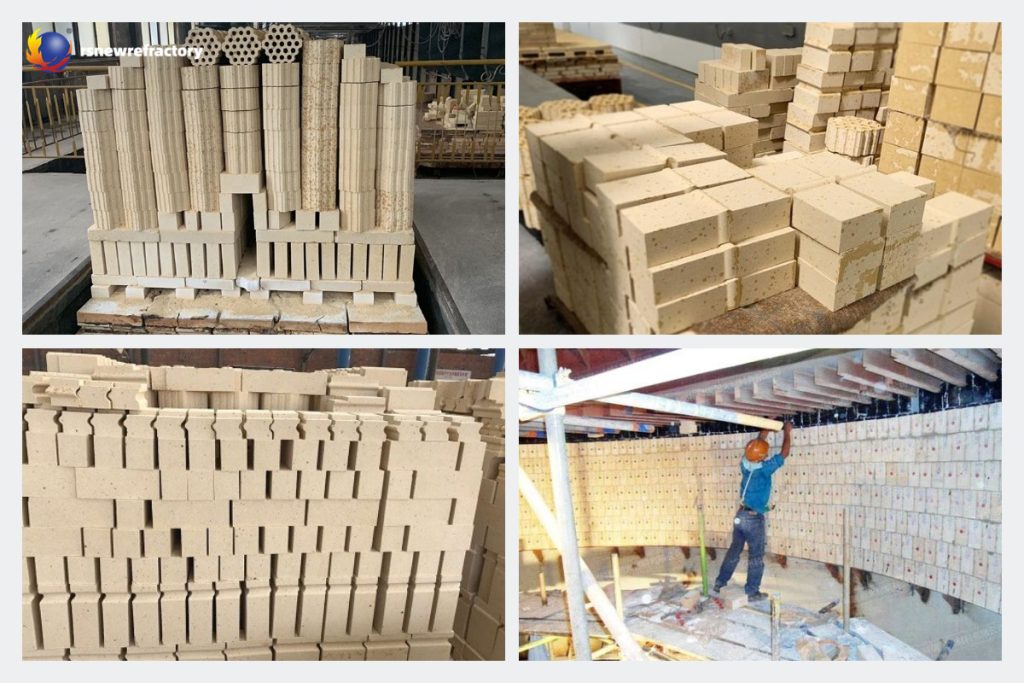

Semi-silica bricks are mainly used as linings for steel ladle and refractory layers for pouring steel systems. In addition, they can also be used for hot furnace roofs, regenerator checker bricks, cupola linings, various kiln bottoms and flues.

Semi-silica brick factory production process

- Raw material selection: Select raw materials with high silicon and aluminum content, such as clay and quartz.

- Mixing and homogenization: Mix and homogenize the raw materials to ensure uniform distribution of the ingredients.

- Molding: Use molding methods such as pressing or extrusion to make bricks of the required shape.

- Drying: The bricks are dried in a drying room to remove moisture.

- Firing: High-temperature firing in a tunnel kiln or shuttle kiln to form hard semi-silica bricks.

- Inspection and grading: The fired semi-silica bricks are inspected for quality and graded according to size, appearance, and performance.

Rongsheng company introduction

Rongsheng Company is a professional supplier of refractory materials, with 10 taon ng karanasan sa pag export, exporting to more than 80 countries. The main products of Rongsheng Company include various refractory bricks, mga materyales na walang hugis refractory, metallurgical materials, thermal insulation materials and so on.

Rongsheng Refractories Pabrika

Rongsheng Refractories Pabrika

WeChat

Scan ang QR Code sa wechat