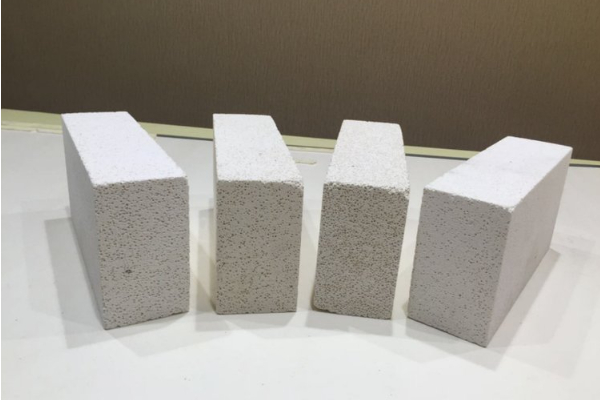

What are lightweight insulation bricks?

Lightweight insulation bricks are a type of thermal insulation material, which refers to insulation bricks with high porosity, low volume density, at mababang thermal kondaktibiti. Lightweight insulation bricks are characterized by a porous structure (porosity is generally 40 sa 85%) and high thermal insulation.

What are the classification methods of lightweight insulation bricks?

- Classified by volume density. Those with a bulk density between 0.4 and 1.3g/cm3 are lightweight insulation bricks; those with a volume density below 0.4g/cm3 are ultra-lightweight insulation bricks.

- Classified by use temperature. The use temperature is 600-900℃ for low-temperature insulation materials; the temperature between 900-1200℃ is medium-temperature insulation material; the temperature exceeding 1200℃ is for high-temperature insulation material.

- Classification according to product shape. One is stereotyped lightweight insulation bricks, including clay insulation bricks, high alumina insulation bricks, silica insulation bricks, and some pure oxide lightweight insulation bricks; the other is unshaped lightweight insulation bricks, such as lightweight insulation castables, atbp.

What are the types of lightweight insulation bricks?

The most common types of lightweight insulation bricks include : diatomite lightweight insulation bricks; mullite pagkakabukod brick; alumina hollow ball bricks; high alumina poly light insulation bricks; lightweight clay bricks; lightweight silica bricks, atbp.

Lightweight insulation brick dimensions

The most common standard size of lightweight insulation brick (lightweight refractory bricks) is (230*114*65mm); According to the size specifications, they are divided into general refractory bricks and special-shaped refractory bricks. The general size refers to the lightweight insulation bricks (lightweight refractory bricks) of other sizes that can be used during construction to complete the construction of the kiln insulation layer.

What is the function of insulation bricks?

Lightweight insulation bricks have the advantages of reducing the weight of the kiln, thinning the walls of the kiln, changing the structure of the kiln, increasing the heating speed, reducing energy consumption, improving working conditions, and improving work efficiency. Lightweight insulation bricks are resistant to high temperatures, have high volume density, high strength, are wear-resistant, and are resistant to acid and alkali erosion. They are widely used in high-temperature kilns such as metallurgy, industriya ng kemikal, electronics, and glass.

What are the advantages of lightweight insulation brick?

The heat storage loss of industrial kiln masonry and the heat dissipation loss of the furnace body generally account for about 24 sa 45% of fuel consumption. Using lightweight insulation bricks with low thermal conductivity and small heat capacity as the furnace body structural material can save fuel consumption; at the same time, because the kiln can heat up and cool down quickly, it can improve equipment production efficiency; it can also reduce the weight of the furnace body and simplify the kiln. The furnace structure improves the quality of insulation bricks, reduces ambient temperature, and improves working conditions.

What is the difference between lightweight bricks and heavy refractory bricks?

1. Insulation performance

The thermal conductivity of lightweight insulation bricks is generally 0.2-0.4 (average temperature 350±25℃) w/m.k, while the thermal conductivity of refractory bricks is above 1.0 (average temperature 350±25℃) w/m.k. It can be concluded that The thermal insulation performance of insulation bricks is much better than that of refractory bricks.

2. Refractory resistance

The fire resistance of lightweight insulation bricks is generally below 1400 degrees, while the fire resistance of refractory bricks is above 1400 degrees.

3. Density

Lightweight insulation bricks are generally lightweight insulation materials with a density generally between 0.8-1.0g/cm3, while the density of refractory bricks is basically above 2.0g/cm3.

4. Utilized location

Lightweight insulating bricks generally do not come into direct contact with flames, high-temperature melts, and erosion by chemical gases. Refractory bricks can withstand direct flame roasting and various erosions by high-temperature melts in the kiln depending on their different materials and physical and chemical properties.

Rongsheng Refractories Pabrika

Rongsheng Refractories Pabrika

WeChat

Scan ang QR Code sa wechat