Banayad na timbang mataas na alumina bubble brick kalamangan

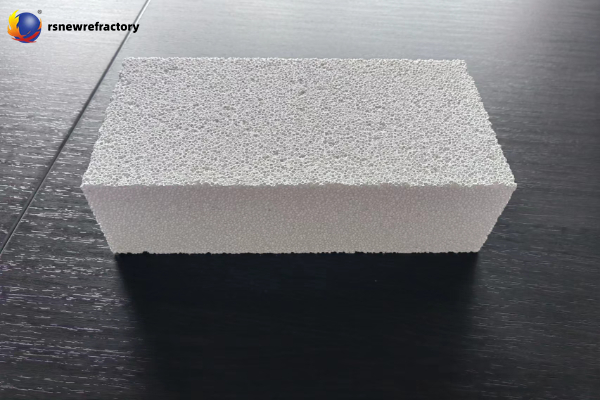

Lightweight hollow alumina balls are a new type of high-temperature heat-insulating material. They are made by melting and blowing industrial alumina in an electric furnace. The crystal form is a-Al2O3 microcrystals. Kasama ang hollow alumina balls as the main body, various shapes of products can be made. The maximum use temperature is 1800℃. The mechanical strength of light weight high alumina bubble brick is high, which is several times that of general lightweight products, and the volume density is only half of that of corundum products.

Banayad na timbang mataas na alumina bubble brick kalamangan

High operating temperature

It can reach over 1750 degrees, with good thermal stability. The re-burning line has a small change rate and a longer service life.

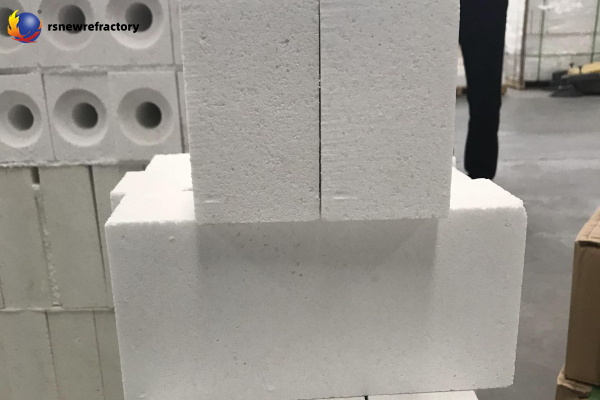

Optimize the structure and reduce the weight of the furnace

Commonly used high-temperature resistant materials are heavy bricks with a volume density of 2.6-3.0g/cm, while alumina hollow ball bricks are only 1.1~1.5g/cm. Compared with other refractory bricks with the same volume of one cubic meter, the use of alumina hollow ball bricks can reduce the weight by 1.1-1.9 tons. It will achieve significant results in reducing the weight of the furnace, modifying the structure, saving materials, and saving energy.

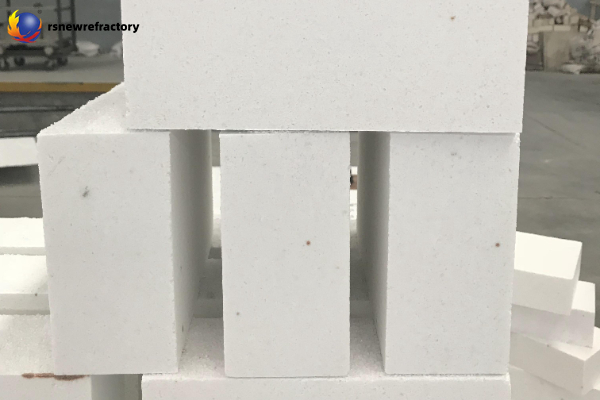

Saving refractory materials

If you want to achieve the same operating temperature, you can use heavy bricks. Their price is comparable to that of alumina hollow ball bricks, and a certain amount of insulation refractory materials is also required. If you use alumina hollow ball bricks, you can save 1.1-1.9 tons of heavy bricks per cubic meter and 80% of refractory insulation materials.

Save energy

Alumina hollow balls have obvious heat preservation properties and low thermal conductivity, which can play a good role in heat preservation, reduce heat dissipation, improve thermal efficiency, and thus achieve the purpose of energy saving. The energy-saving effect can reach more than 30%.

Rongsheng Refractories Pabrika

Rongsheng Refractories Pabrika

WeChat

Scan ang QR Code sa wechat