Ayudar a las empresas de Bosnia y Herzegovina a reparar hornos de alta temperatura

A leading industrial company in Bosnia and Herzegovina has introduced Rongsheng’s refractory materials for the repair of high-temperature kilns. The products purchased by customers include JM28/high alumina bricks, barro refractario, and ceramic fiber blankets. These high-performance materials bring great value to customers.

Problems encountered by customers in Bosnia and Herzegovina

This company in Bosnia and Herzegovina has been facing the limitations of traditional refractory materials in high-temperature processes, including rapid wear and high maintenance costs. To improve production efficiency, reduce energy consumption, and extend equipment life, they began to look for better weather-resistant materials for high-temperature kiln repairs.

Solutions for customers

The customer chose to introduce the following three high-performance refractory materials:

JM28/high alumina brick: Known for its excellent high-temperature stability and corrosion resistance, this brick provides a longer-lasting lining for customers’ high-temperature kilns.

Cemento refractario: Highly refractory mud is used to maintain and repair the inner walls of the kiln to enhance its overall durability.

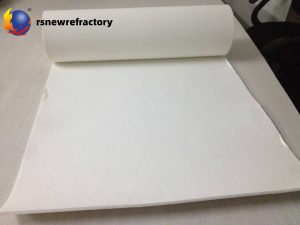

Manta de fibra cerámica: This lightweight, high-insulating fiber blanket is used as the thermal insulation layer of the kiln to effectively reduce energy loss and improve equipment efficiency.

What changes have Rongsheng refractory bricks brought to customers?

- High-temperature kiln upgrade: The introduction of JM28/high alumina bricks enables customers to upgrade high-temperature kilns, stabilize temperatures, and improve production quality.

- High-temperature kiln repair and maintenance: Refractory mud is used for maintenance and repair inside the kiln, extending the service life of the equipment and reducing downtime.

- Energy efficiency improvement: The application of ceramic fiber blankets effectively reduces heat loss and energy consumption, bringing significant energy efficiency improvements to enterprises.

Fábrica de refractarios de Rongsheng

Fábrica de refractarios de Rongsheng

WeChat

Escanea el código QR con wechat