El ladrillo de semisílice es un producto refractario de silicato de aluminio con alúmina. (Al2O3) contenido de 15-30%, y es un ladrillo refractario semiaácido. Los ladrillos de semisílice generalmente utilizan arcilla refractaria que contiene arena de cuarzo., pirofilita, arcilla refractaria, o relaves de beneficio de caolín como materia prima. Los ladrillos de semisílice se encogen menos durante la cocción, porque a 1250°C, el cuarzo de la materia prima se convierte en cristobalita, y el volumen se expande, que compensa parcialmente la contracción producida durante la sinterización de la arcilla.. El proceso de fabricación de ladrillos de semisílice se puede dividir en dos tipos.: despedido o no despedido. El proceso de fabricación de los ladrillos cocidos es básicamente el mismo que el de los ladrillos de arcilla.; Los ladrillos sin cocer se fabrican principalmente con vidrio soluble como aglutinante..

Detalles de ladrillo de semisílice

| Nombre del producto | Ladrillo de semisilicio |

| AI2O3/% | 21.59 |

| SiO2/% | 76.58 |

| Fe2O3/% | 0.83 |

| Refractariedad ℃ | 1630-1650 |

| Densidad aparente g/cm³ | 2.1 |

| Porosidad aparente % | 18 |

| Resistencia a la compresión a temperatura normal / MPa | 29 |

| Temperatura de ablandamiento de carga(T6.6) / ºC | 1490 |

Características de los ladrillos de semisílice.

Refractario: La refractariedad de los ladrillos de semisílice suele estar entre 1580°C y 1680°C..

Resistencia a la corrosión química: Tiene buena resistencia a la corrosión contra escorias ácidas y alcalinas..

Estabilidad térmica: Tiene buena estabilidad térmica y es adecuado para entornos con grandes fluctuaciones de temperatura..

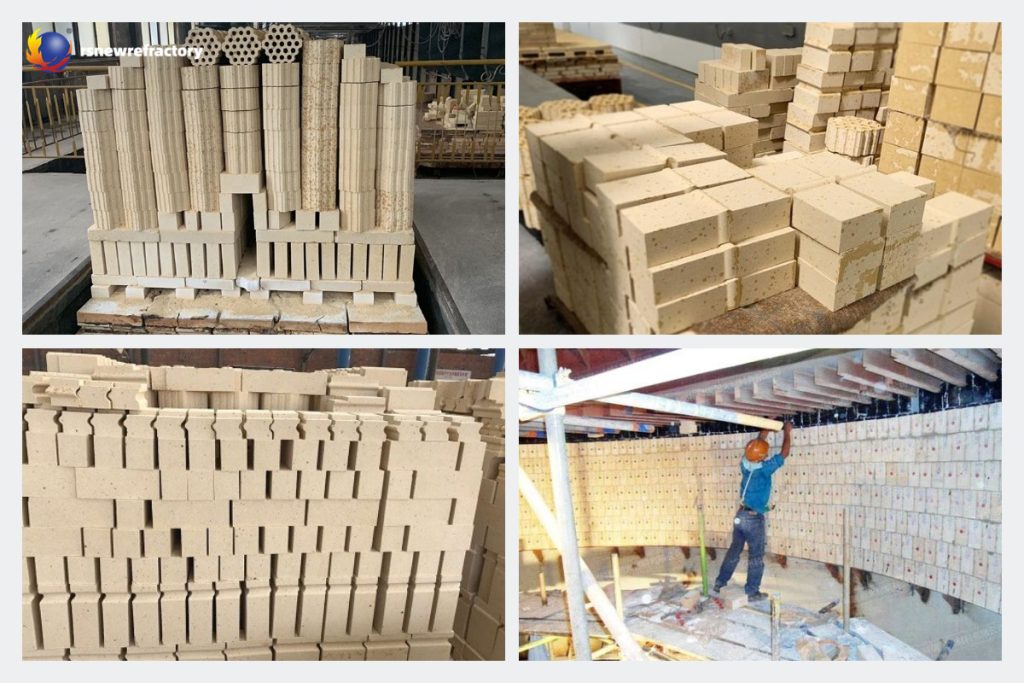

Aplicación de ladrillos de semisílice

Los ladrillos de semisílice tienen un volumen estable a altas temperaturas. (ligeramente expandido), Lo cual es beneficioso para mejorar la integridad de la mampostería y reducir la erosión de la escoria en la mampostería.; cuando está en contacto con escoria de alta temperatura, Se forma una capa de sustancia viscosa similar a un esmalte en la superficie del ladrillo., bloquear los poros y evitar que la escoria penetre en el ladrillo, mejorando así la capacidad antierosión del ladrillo; y la temperatura de deformación de carga es relativamente alta; así que en algunas ocasiones, su vida útil no es inferior a la de los ladrillos de arcilla ordinarios.

Los ladrillos de semisílice se utilizan principalmente como revestimientos para cazos de acero y capas refractarias para sistemas de vertido de acero.. Además, También se pueden utilizar para techos de hornos calientes., ladrillos de inspector regenerador, revestimientos de cúpula, varios fondos de horno y chimeneas.

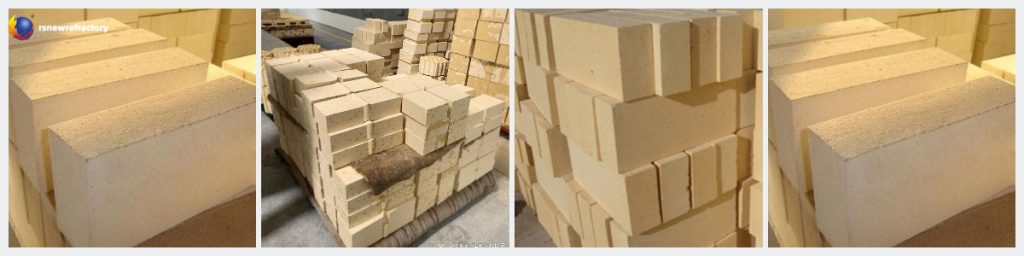

Proceso de producción en fábrica de ladrillos de semisílice.

- Selección de materia prima: Seleccionar materias primas con alto contenido de silicio y aluminio., como arcilla y cuarzo.

- Mezclado y homogeneización.: Mezclar y homogeneizar las materias primas para asegurar una distribución uniforme de los ingredientes..

- Moldura: Utilice métodos de moldeo como prensado o extrusión para hacer ladrillos con la forma requerida..

- El secado: Los ladrillos se secan en una sala de secado para eliminar la humedad..

- Disparo: Cocción a alta temperatura en un horno de túnel o en un horno lanzadera para formar ladrillos duros de semisílice.

- Inspección y clasificación: Los ladrillos cocidos de semisílice se inspeccionan para comprobar su calidad y se clasifican según el tamaño., apariencia, y rendimiento.

Introducción de la empresa Rongsheng

Rongsheng Company es un proveedor profesional de materiales refractarios, con 10 años de experiencia exportadora, exportando a más de 80 países. Los principales productos de Rongsheng Company incluyen varios ladrillos refractarios, materiales refractarios sin forma, materiales metalúrgicos, materiales de aislamiento térmico y así sucesivamente.

Fábrica de refractarios de Rongsheng

Fábrica de refractarios de Rongsheng

WeChat

Escanea el código QR con wechat