Cuatro métodos de vertido para ladrillos de corindón de circonio fundido

Los ladrillos de corindón fundido se fabrican fundiendo alúmina en un horno de arco eléctrico y moldeándola en un modelo de una forma específica específica.. Después del recocido y conservación del calor., el producto requerido se obtiene procesando con herramientas abrasivas de diamante.

Introducción a los ladrillos de corindón de circonio fundido.

Este producto se divide en tres tipos según las diferentes formas cristalinas y cantidades de alúmina.. El primer tipo se basa en α-Al2O3 como fase cristalina principal., que se llama α- ladrillo de corindón; el segundo tipo se basa en α-Al2O3 y β-Al2O3. La fase cristalina principal es básicamente 1:1, y el contenido de fase α es ligeramente mayor, que se llama α, b- ladrillo de corindón; el tercer tipo es principalmente fase cristalina β-Al2O3, que se llama β- ladrillo de corindón.

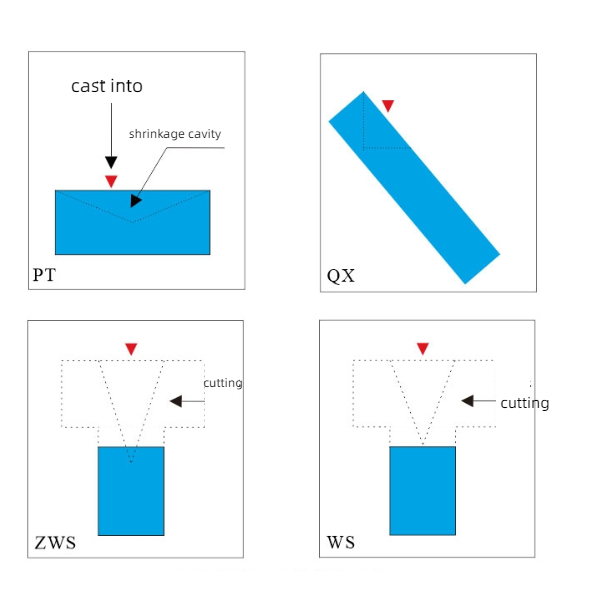

Cuatro métodos de vertido de ladrillo AZS

cuando el ladrillo de corindón de circonio fundido solidifica, El cambio de volumen causado por la transición de líquido a sólido produce cavidades de contracción de aproximadamente 15%-25%. Como resultado, Existen varios métodos de fundición que utilizan fundición con agua caliente para minimizar las cavidades de contracción de los ladrillos de corindón de circonio fundido., y tener en cuenta el estado de erosión de la pieza de uso para concentrar las cavidades de contracción en un extremo.

- casting ordinario (PT) método de fundición común. La cavidad de contracción en el ladrillo de corindón de circonio fundido se encuentra en la parte inferior de la abertura de fundición.. Se utiliza en piezas como la estructura superior de los hornos de fusión de vidrio donde la corrosión es relativamente lenta..

- fundición inclinada (qx) Adopta el método de fundición inclinada., y los orificios de contracción en los ladrillos de corindón de circonio fundido están desplazados en el extremo inferior (Utilice ladrillos secos para la pared de la piscina.). Es a través del método de aislamiento inclinado que los orificios de contracción se dirigen a la parte inferior cuando se utilizan.. Por lo tanto, sus agujeros de contracción se concentran en un extremo del ladrillo, mientras que el otro extremo es denso. Los ladrillos de corindón de circonio fundido se utilizan generalmente en las partes de la pared del tanque de fusión del horno de vidrio correspondientes a la erosión de la línea de nivel de líquido del vidrio..

- Fundición sin contracción (WS): Después de que la fundición se haya enfriado y condensado., la parte de la cavidad de contracción se retira del ladrillo de corindón de circonio fundido sin cavidad de contracción. Generalmente, agujeros líquidos del horno de vidrio seco, paredes de la piscina, y se utilizan otras piezas altamente corrosivas.

- Fundición casi sin contracción (ZWS) es lo mismo que ZWS, que es un ladrillo de corindón de circonio fundido al que se le han eliminado casi por completo las cavidades de contracción. Las cavidades de contracción también se concentran en la boca de fundición.. Una vez enfriada la pieza fundida, la mayoría de las cavidades de contracción se eliminan, dejando solo una cantidad muy pequeña de cavidades de contracción en la superficie de corte. Generalmente se utiliza como ladrillos de pared para piscinas de fusión de hornos de vidrio..

Fábrica de refractarios de Rongsheng

Fábrica de refractarios de Rongsheng

WeChat

Escanea el código QR con wechat