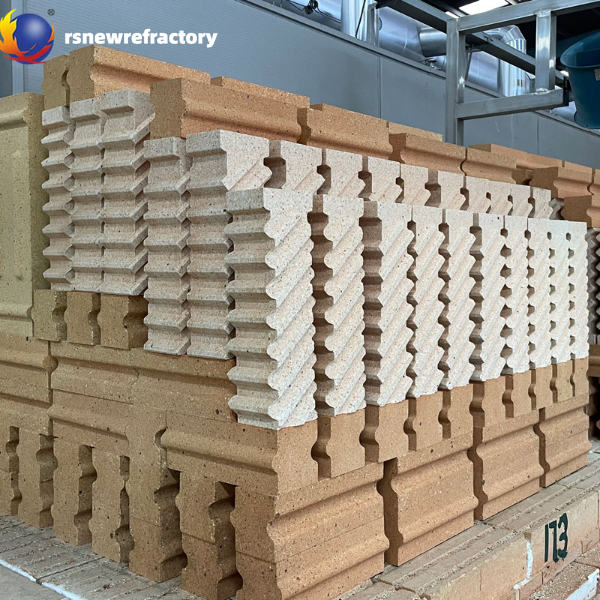

Clasificación de ladrillos refractarios de anclaje.

Los ladrillos refractarios de anclaje son un material especial ampliamente utilizado en hornos industriales de alta temperatura para soportar y fijar la estructura del revestimiento refractario.. Debido a su diseño único, ladrillos de anclaje Puede mejorar efectivamente la resistencia y estabilidad del revestimiento refractario y extender la vida útil del equipo.. Este artículo presentará en detalle la clasificación de los ladrillos de anclaje refractarios y sus aplicaciones específicas en la industria..

Clasificación de ladrillos refractarios de anclaje.

Ladrillo de anclaje con alto contenido de alúmina

Materias primas: La bauxita con alto contenido de alúmina es la principal materia prima., y el contenido de alúmina suele ser superior 48%.

Características: Tiene buena resistencia a altas temperaturas y resistencia a la corrosión., y es ampliamente utilizado en la industria del acero y hornos de cemento..

Solicitud: Se utiliza en áreas donde se requiere alta resistencia y resistencia al desgaste en hornos de alta temperatura..

Ladrillos de anclaje de arcilla

Materias primas: La arcilla refractaria es la principal materia prima., con contenido de alúmina relativamente bajo.

Características: Rendimiento de alto costo, adecuado para hornos de temperatura media o áreas de carga de baja calor.

Solicitud: Aplicado a la fijación del revestimiento de hornos pequeños y medianos..

Ladrillo de anclaje de corindón

Materias primas: corindón fundido o corindón sinterizado como principales materias primas, con un contenido de alúmina superior a 90%.

Características: resistencia a la corrosión y al desgaste extremadamente fuertes, excelente resistencia a la temperatura.

Solicitud: Se utiliza en hornos industriales de alta temperatura que requieren resistencia a temperaturas extremadamente altas y resistencia a la corrosión..

Ladrillo de anclaje de carburo de silicio

Materias primas: El carburo de silicio es el componente principal., generalmente con algo de aglutinante agregado.

Características: fuerte resistencia al desgaste, excelente conductividad térmica, excelente resistencia al choque térmico.

Solicitud: Adecuado para áreas de enfriamiento de hornos de alta temperatura y áreas que requieren una rápida disipación del calor..

Campos de aplicación de los ladrillos de anclaje refractarios.

Industria metalúrgica

Aplicado para fijar el revestimiento refractario de altos hornos., hornos de arco electrico, y convertidores, y resistir la erosión del metal fundido y la escoria a alta temperatura.

Industria del cemento

Utilizado en hornos rotativos de cemento., hornos de descomposición,s, y otras piezas para la fijación de hormigones y ladrillos refractarios.

industria del vidrio

Se utiliza en la cámara de almacenamiento de calor y en el techo de los hornos de vidrio para soportar la estructura del horno y resistir la erosión de los gases de alta temperatura..

Industria petroquímica

Se utiliza en dispositivos de alta temperatura, como hornos de craqueo y hornos de gasificación, para fijar moldes refractarios y capas aislantes..

Otros campos

Incluyendo equipos de hornos de alta temperatura, como hornos cerámicos., incineradores de residuos, y hornos industriales de aluminio.

Fábrica de refractarios de Rongsheng

Fábrica de refractarios de Rongsheng

WeChat

Escanea el código QR con wechat