Breve introducción de la estructura y función refractaria de la cuchara de acero

La cuchara de acero refractario también se llama revestimiento refractario de cuchara., que se utiliza para sujetar acero fundido. El acero fundido también se somete a refinación y otras operaciones de proceso en la cuchara.. El cucharón de acero se compone de tres partes.: la capa exterior, el forro, y el mecanismo de control de inyección.

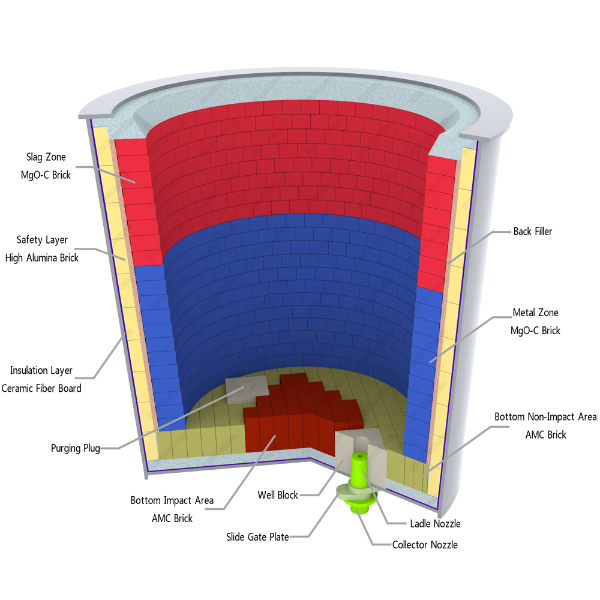

Estructura refractaria de cuchara de acero.

La carcasa de la cuchara está soldada a partir de placas de acero de caldera., y el espesor de la pared del barril y las placas de acero del fondo del barril es de aproximadamente 14 ~ 30 mm y 24 ~ 40 mm. Para garantizar una eliminación suave de la humedad del horneado., 8Se perforan pequeños agujeros de ~10 mm en la carcasa del cucharón.. Además, Las nervaduras de refuerzo y los aros de refuerzo están soldados en la cintura de la carcasa del cucharón..

Introducción al revestimiento refractario de la cuchara.

El revestimiento del cazo está compuesto por una capa aislante., una capa permanente, y una capa de trabajo. La capa de aislamiento está cerca de la placa de acero y tiene entre 10 y 15 mm de espesor.. Se utiliza principalmente para reducir la pérdida de calor y, a menudo, se construye con tableros de amianto.: Para evitar que el acero fundido se queme a través del cucharón., También hay una capa permanente dentro de la capa aislante., que tiene aproximadamente 30 ~ 60 mm de espesor. Esta capa está construida con ladrillos de arcilla y ladrillos con alto contenido de alúmina; la capa de trabajo de la cuchara está en contacto directo con el acero fundido y la escoria. Estará directamente sujeto a fregado mecánico, enfriamiento y calentamiento rápidos y es propenso a pelarse.. La vida del cucharón está relacionada con la calidad de esta capa.. Esta capa suele construirse de forma integral., eso es, el fondo del cucharón está hecho de ladrillos encerados o ladrillos con alto contenido de alúmina, la pared del cucharón está hecha de ladrillos con alto contenido de alúmina y ladrillos de aluminio y carbono., y la línea de escoria a menudo está hecha de ladrillos de magnesio y carbono.

Sistema de control de acero fundido de cuchara de acero.

La apertura de la boquilla deslizante del cucharón se utiliza para controlar el tamaño del flujo de acero y la altura del nivel del líquido de la artesa.. La boquilla deslizante consta de una boquilla superior, una placa deslizante superior, una boquilla inferior, y un placa deslizante inferior. Durante la operación, El movimiento de la placa deslizante inferior se puede utilizar para ajustar la superposición de los orificios de inyección superior e inferior y así controlar el tamaño del flujo de inyección.. Hay dos formas de ajustarlo., es decir, hidráulico y manual. desde el boquilla deslizante Tiene que resistir la desoxidación de escorias a alta temperatura., La presión estática del acero fundido., y los efectos del enfriamiento y calentamiento rápidos, Se requiere que el material refractario sea resistente a altas temperaturas., fregado, enfriamiento y calentamiento rápidos, y tener buena resistencia a la escoria, y tener suficiente resistencia a altas temperaturas. Actualmente, Los materiales más utilizados son el alto contenido de aluminio., magnesio, compuestos de magnesio y aluminio, etc., y también hay placas deslizantes empapadas en asfalto para aumentar la vida útil de la placa deslizante..

La boquilla superior está situada entre el cucharón y la artesa.. Durante la producción, Hay un conjunto de dispositivos especiales de instalación de boquilla larga en el sitio para colgarlo en la boquilla inferior., para evitar que el flujo de inyección entre la cuchara y la artesa sea una oxidación secundaria, al mismo tiempo, También puede evitar las salpicaduras del flujo de inyección y el problema de la escoria rodante de la fundición abierta.. Los materiales de la boquilla larga son principalmente cuarzo fundido y carbono de alúmina..

Fábrica de refractarios de Rongsheng

Fábrica de refractarios de Rongsheng

WeChat

Escanea el código QR con wechat