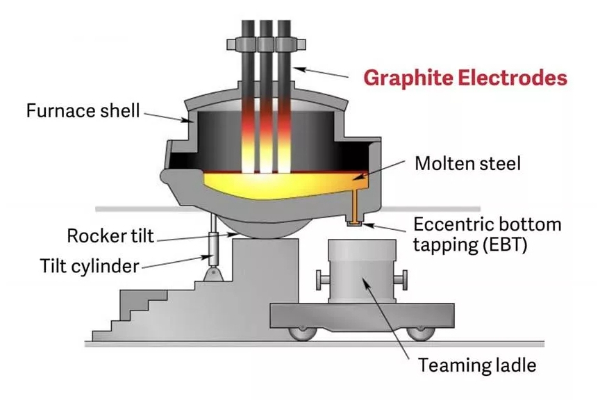

Graphite electrodes and nipples are essential components used in electric arc furnaces for the production of steel and other metals.

Graphite electrodes and nipples are critical components in the steelmaking process, as they play a crucial role in generating the high temperatures required to melt and refine metals. The quality and performance of the electrodes and nipples are essential to the overall efficiency and productivity of the electric arc furnace, and therefore they must be manufactured to strict quality standards.

Graphite electrodes and nipple details

Graphite Electrode

| Είδος | Nominal diameter mm | ||||||||||

| 75~130 | 150~225 | 250~300 | 350~450 | 500~800 | |||||||

| Βαθμός | Excellent | 一 | Ex | 一 | Ex | 一 | Ex | 一 | Ex | 一 | |

| Resistivity μΩ·m ≤ | Electrode | 8.5 | 10.0 | 9.0 | 10.5 | 9.0 | 10.5 | 9.0 | 10.5 | 9.0 | 10.5 |

| Connector | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | ||||||

| Flexural strength MPa ≥ | Electrode | 10.0 | 10.0 | 8.0 | 7.0 | 6.5 | |||||

| Connector | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | ||||||

| Elastic Modulus GPa ≤ | Electrode | 9.3 | 9.3 | 9.3 | 9.3 | 9.3 | |||||

| Connector | 14.0 | 14.0 | 14.0 | 14.0 | 14.0 | ||||||

| Bulk density g/cm3 ≥ | Electrode | 1.58 | 1.53 | 1.53 | 1.53 | 1.52 | |||||

| Connector | 1.70 | 1.70 | 1.70 | 1.70 | 1.70 | ||||||

| Thermal expansion coefficient 10-6/℃ room temperature ~600℃ ≥ | Electrode | 2.9 | 2.9 | 2.9 | 2.9 | 2.9 | |||||

| Connector | 2.7 | 2.7 | 2.8 | 2.8 | 2.8 | ||||||

| Ash % ≤ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | ||||||

High Power Graphite Electrodes

| Είδος | Nominal diameter mm | |||

| 200~400 | 450~500 | 550~700 | ||

| Resistivity μΩ·m ≤ | Electrode | 7.0 | 7.5 | 7.5 |

| Connector | 6.3 | 6.3 | 6.3 | |

| Flexural strength MPa ≥ | Electrode | 10.5 | 10.0 | 8.5 |

| Connector | 17.0 | 17.0 | 17.0 | |

| Elastic Modulus GPa ≤ | Electrode | 14.0 | 14.0 | 14.0 |

| Connector | 16.0 | 16.0 | 16.0 | |

| Χύδην πυκνότητα g/cm3 ≥ | Electrode | 1.60 | 1.60 | 1.60 |

| Connector | 1.72 | 1.72 | 1.72 | |

| Thermal expansion coefficient 10-6/℃ Room temperature~600℃ ≥ | Electrode | 2.4 | 2.4 | 2.4 |

| Connector | 2.2 | 2.2 | 2.2 | |

| Ash % ≤ | 0.5 | 0.5 | 0.5 | |

Ultra High Power Graphite Electrode

| Είδος | Nominal diameter mm | ||||

| 300~400 | 450~500 | 550~650 | 700~800 | ||

| Resistivity μΩ·m ≤ | Electrode | 6.2 | 6.3 | 6.0 | 5.8 |

| Connector | 5.3 | 5.3 | 4.5 | 4.3 | |

| Flexural strength MPa ≥ | Electrode | 10.5 | 10.5 | 10.0 | 10.0 |

| Connector | 20.0 | 20.0 | 22.0 | 23.0 | |

| Elastic Modulus GPa ≤ | Electrode | 14.0 | 14.0 | 1.66 | 14.0 |

| Connector | 20.0 | 20.0 | 1.78 | 22.0 | |

| Χύδην πυκνότητα g/cm3 ≥ | Electrode | 1.67 | 1.66 | 1.66 | 1.68 |

| Connector | 1.74 | 1.75 | 1.78 | 1.78 | |

| Thermal expansion coefficient 10-6/℃ Room temperature~600℃ ≥ | Electrode | 1.5 | 1.5 | 1.5 | 1.5 |

| Connector | 1.4 | 1.4 | 1.3 | 1.3 | |

| Ash % ≤ | 0.5 | 0.5 | 0.5 | 0.5 | |

Graphite electrode applications

- Electric arc furnace for electric arc furnace.

- Used in ore thermal electric furnace.

- Used in resistance furnaces

- Used to prepare special-shaped graphite products.

Advantages of graphite electrodes

- Αντοχή στη διάβρωση: Graphite electrodes have excellent corrosion resistance and can resist the erosion of many strong acids, alkalis, solvents, and other corrosive substances. This makes them suitable for many industrial processes with corrosive environments.

- High-temperature stability: Graphite electrodes remain stable at high temperatures, which allows them to be used in high-temperature reactions and processes, such as electric arc furnaces, high-temperature electrolysis, και τα λοιπά.

- Conductive properties: Graphite is an excellent conductive material and can effectively conduct electric current.

- Υψηλή μηχανική αντοχή: Graphite electrodes have high mechanical strength and hardness, making them less likely to deform or break during use.

- Ease of Processing: Graphite is relatively easy to process into various shapes and sizes and can be customized to specific application needs.

- Oxidation resistance: Graphite electrodes have specific oxidation resistance.

Graphite electrode transportation and delivery

Εισαγωγή της εταιρείας Rongsheng

Η Rongsheng Company είναι επαγγελματίας προμηθευτής πυρίμαχων υλικών, με 10 χρόνια εμπειρίας στις εξαγωγές, εξαγωγή σε περισσότερα από 80 χώρες. Τα κύρια προϊόντα της Rongsheng Company περιλαμβάνουν διάφορα πυρίμαχα τούβλα, άμορφα πυρίμαχα υλικά, μεταλλουργικά υλικά, θερμομονωτικά υλικά, και ούτω καθεξής.

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Σαρώστε τον κωδικό QR με το wechat