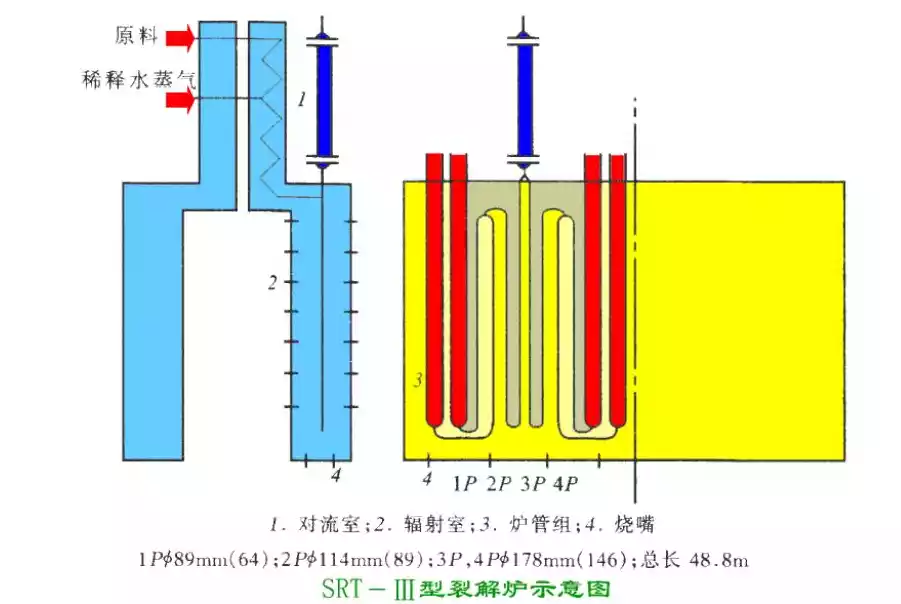

The cracking furnace is the core of ethylene production, and the refractory material is an important factor affecting the service life of the cracking furnace. Among them, the lining and working group of the SRT cracking furnace use refractory materials.

SRT cracking furnace

Refractories for SRT cracking furnace

In the internal high temperature area of the cracking furnace, refractory bricks are used to construct the wall and bottom of the furnace.

Refractory castables:

Refractory castables are used to fill and repair small gaps and damaged parts of furnaces.

Used for the insulation layer of the furnace.

In the external area of the pyrolysis furnace, insulation bricks are used to reduce heat conduction and heat loss.

Thermal barrier coating:

The external surfaces of the pyrolysis furnace are coated with a thermal barrier coating. These coatings are usually made of ceramic fibers, refractory cement and other materials, which can provide better heat insulation effect.

Κουβέρτα από κεραμικές ίνες

| Θερμοκρασία ταξινόμησης ℃ | 1140 | 1260 | 1400 | ||

| Βαθμός | XT114 | XT126-A | XT126-B | XT140-A | XT140-B |

| Permanent linear change % ℃×24 ώρες | ≤-3 950 | ≤-3 1000 | ≤-3 1100 | ≤-3 1200 | ≤-3 1350 |

| Θερμική αγωγιμότητα W/(m·K)500℃ | ≤0,153 | ||||

| Αντοχή εφελκυσμού MPa 25mm πάχος | >0.04 | >0,05 | >0.04 | >0.06 | |

| Χύδην πυκνότητα kg/m3 | 64/96/128/160 | ||||

| Ο Αλ2Ο3 % | ≥44 | ≥45 | ≥45 | ≥52 | ≥36 |

| SiO2 % | ≥52 | ≥52 | ≥54 | ≥46 | ≥48 |

| ZrO2 % | / | / | / | / | ≥15 |

| Fe2Ο3 % | ≤1,0 | ≤0,8 | ≤0,2 | ≤0,2 | ≤0,1 |

| Ο Αλ2Ο3+SiO2 % | ≥96 | ≥97 | ≥99 | ≥99 | ≥ |

| Ο Αλ2Ο3+SiO2+ZrO2 % | / | / | / | / | 99 |

| Μέγεθος | 3600/7200×610×20/30/50 | ||||

Refractory plastic

| Είδος | Καρβίδιο του πυριτίου | Zirconium Chrome Corundum | ||

| NMK4 | NMK5 | NMK6 | NMK7 | |

| Al2O3 % | / | / | / | ≥80 |

| Ούτω % | ≥40 | ≥60 | ≥70 | / |

| Cr2O3 % | / | / | / | ≥3 |

| ZrO2 % | / | / | / | ≥2 |

| Bulk Density g/cm3 110℃×24 ώρες | ≥2.4 | ≥2,5 | ≥2.6 | ≥2.8 |

| Permanent Linear Change % 1000℃×3 ώρες | -0.4~0 | -0.5~0 | -0.6~0 | -0.6~0 |

| Cold Crush Strength MPa 1000℃×3 ώρες | ≥60 | ≥70 | ≥80 | ≥90 |

| Wear resistance at room temperature cm3 1000℃×3 ώρες | ≤7 | ≤6 | ≤5 | ≤5 |

| Thermal shock stability cycle 1000℃ water cooling | ≥30 | ≥35 | ≥40 | ≥30 |

| Plasticity Index % | 15~55 | |||

| Plasticity W/(m·K) 1000℃ | 3~ 5 | 5~7 | 6~8 | 2~3 |

| Maximum service temperature ℃ | 1400 | 1500 | 1600 | 1600 |

High alumina refractory castable

| Δείκτης | High Alumina Castable | |

| Al2o3 % | 65 | |

| Sio2 % | 30 | |

| Cao % | 6 | |

| Bulk density g/cm³ | 110℃,24η | 2.5 |

| 1350℃,24η | 2.6 | |

| Cold bending strength MPA | 110℃,24η | 6 |

| 1350℃,24η | 7.5 | |

| Hot bending strength MPA | 110℃,24η | 45 |

| 1350℃,24η | 60 | |

| 1350 Burning line rate of change | 0.2 | |

| Mixing water consumption % | 10-12% | |

| Operating temperature | 1400 | |

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Σαρώστε τον κωδικό QR με το wechat