90% of Corundum Brick Production Completed

Recently, the factory completed a batch of 90% of corundum brick. Μετά την παραλαβή της παραγγελίας, Rongsheng Refractory Factory started the production of corundum bricks according to the production plan.

Introduction to corundum bricks

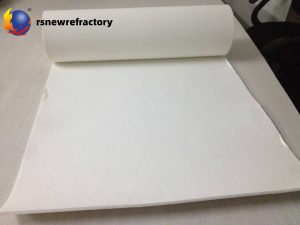

Corundum bricks refer to refractory products with an alumina content greater than 90% and corundum as the main crystal phase. Very high normal temperature compressive strength (up to 340MPa). High load softening onset temperature (greater than 1700°C). It has good chemical stability and strong resistance to acidic or alkaline slag, metal, and glass liquid. Thermal shock stability is related to its organizational structure. The corrosion resistance of dense products is good, but the thermal shock stability is poor.

Characteristics of 90% of corundum brick

90% of corundum brick has the characteristics of high strength, αντοχή στη φθορά, and high-temperature resistance. They are suitable for lining and masonry of various industrial furnaces and can effectively improve the fire resistance and service life of the equipment.

Corundum brick production process

Raw material preparation: Select high-quality corundum ore as the main raw material, and add other auxiliary raw materials as needed, such as calcining aids, binders, και τα λοιπά.

Mixing and grinding: The raw materials are mixed and ground to a certain particle size and uniformity for subsequent molding.

Molding: The mixed raw materials are molded into bricks through a molding machine. Common molding methods include extrusion molding, compression molding, και τα λοιπά.

Drying: Dry the formed bricks to remove moisture and improve the strength of the bricks.

Sintering: The dried bricks are placed in a high-temperature furnace for sintering to crystallize into corundum bricks.

Cooling and inspection: After the sintered corundum bricks are cooled, a quality inspection is carried out to ensure that the product meets the requirements.

Packaging and storage: Qualified corundum bricks are packaged and stored in a dry and ventilated warehouse until they are shipped.

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Σαρώστε τον κωδικό QR με το wechat