Refractory mortar is made into new types of inorganic binder materials by choosing the same powder materials and adding inorganic binder, according to the request of construction materials. There are four grades below NT-1300, NT-1400, NT-1500, and NT-1600, each material is divided into lightweight and heavyweight, and we can choose relevant refractory mortar according to different requests for construction materials.

Parameter des feuerfesten Mörtels

MgO(%) | Al2O3(%) | Cr2O3(%) | Modules of rupture(MPa) | Feuerfestigkeit | Bonding Time | Bonder | ||

| ≥ | ≥ | 110℃ *24h | 1400℃ *3h | (℃) ≥ | (min) | |||

| Magnesia-chrome mortar | 78-85 | – | 3-5 | – | 2 | 1800 | 1-3 | Water glass |

| Magnesia-chrome composite mortar | 90 | – | 1-3 | – | 4 | 1800 | 1-3 | Water glass |

| Magnesia mortar | 85-90 | – | – | – | 3 | 1800 | 1-3 | Water glass |

| Spinel mortar | 80-85 | 4-8 | – | – | 4 | 1800 | 1-3 | Water glass |

| High alumina mortar | – | 60-75 | – | 1 | 4 | 1790 | 1-3 | Water |

| Anti-stripping high alumina mortar | – | 75 | – | 1 | 5 | 1790 | 1-3 | Water |

| Phosphate mortar | – | 70 | – | 1 | 5 | 1790 | 1-3 | Phosphate |

| P901 mortar | – | 75 | – | 1.5 | 6 | 1790 | 1-3 | Phosphate |

| Alkai-resistant mortar | – | 30-35 | – | 1 | 3 | 1690 | 1-3 | Water |

| Insulating alkali-resistant mortar | – | 30-40 | – | 1 | 1.5 | 1650 | 1-3 | Water |

| Silicon mud(RSGN-96) | Sio2%≥96 | 0.6 | – | 0.5 | 1.5 | 1710 | 1-3 | Water |

| Silicon mud(RSGN-94) | Sio2%≥94 | – | – | 1 | 3 | 1690 | 1-3 | Water |

| Silicon heat insulation mud(RSGGN-94) | Sio2%≥94 | – | – | 0.5 | 1.5 | 1690 | 1-3 | Water |

| Silicon heat insulation mud(RSGGN-92) | Sio2%≥92 | – | – | 0.5 | 1.5 | 1670 | 1-3 | Water |

| Wear-resisting refractory mortar | – | – | – | – | 1000℃*3h(4-6) | 1790 | 1-3 | Water |

| Light refractory mortar | – | – | – | – | – | 1650 | 1-3 | Water |

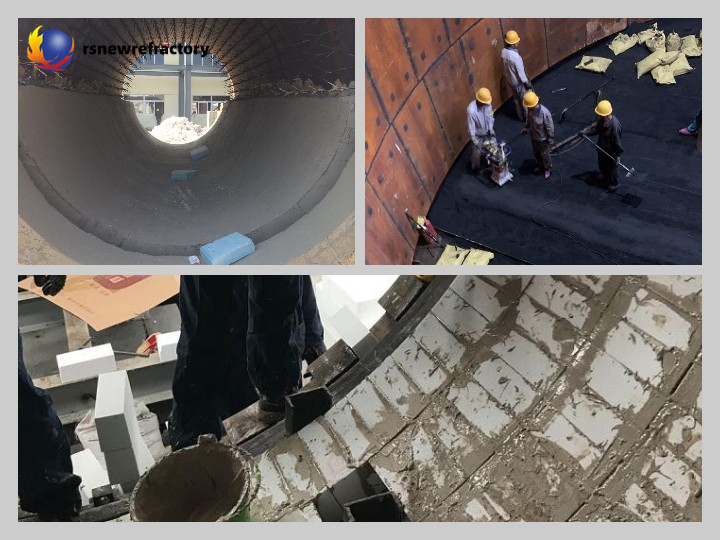

Auftragen von feuerfestem Mörtel

Zu den Anwendungsbranchen gehört die Metallurgie, Baumaterial, Maschinen, Petrochemie, Glas, Kessel, elektrische Energie, Stahl, Zement, usw. Das Material des feuerfesten Mörtels muss mit dem der feuerfesten Mauerwerksprodukte übereinstimmen. Zusätzlich zur Verwendung als Zeigematerial, Feuerfester Schlamm kann durch Auftragen oder Sprühen auch als Schutzschicht für Auskleidungen verwendet werden.

Characteristics of high-heat mortar

Safety: The mortar does not produce sparks when impacted or rubbed, and is particularly suitable for environments with flammable and explosive substances.

Verschleißfest: It has excellent wear resistance, can effectively resist various wear and tear, and extends the service life of the floor.

Anti-slip: Its surface is smooth and has good anti-slip properties, which can effectively reduce accidents.

Anti-static: The mortar has good conductive properties, which can effectively prevent static electricity accumulation and avoid potential dangers.

Bequeme Konstruktion: It can be directly added with water and stirred in proportion, and the construction operation is simple and convenient.

Environmental protection: The mortar does not contain chemicals harmful to the human body and the environment, and meets environmental protection requirements.

Bauprozess von feuerfestem Mörtel

- Grundreinigung. Erstens, Es ist notwendig, die Oberfläche des Fundaments zu reinigen, um Schmutz wie schwebenden Staub und Öl zu vermeiden.

- Nasse Bauoberfläche. Vor der Anwendung, Befeuchten Sie die Oberfläche mit einer Walze oder einem Sprinkler, Beim Auftragen sollte jedoch kein überschüssiges Wasser vorhanden sein.

- Materialien konfigurieren. Mix mortar and water, und Wasser hinzufügen 14-20%, abhängig von der tatsächlichen Situation.

- Glätten Sie die Oberfläche. Der gerührte Mörtel wird auf die Operationsebene gegossen, was innerhalb abgeschlossen werden muss 20 Protokoll.

- Wartung. Nach der Reparatur Wasser versprühen, oder zur Wartung mit Plastikfolie abdecken.

Why choose Rongsheng monolithic refractory company

Newly upgraded fully automatic production line

Rongsheng has a newly upgraded fully automatic production line, which can realize the automatic production of amorphous products such as refractory cement, feuerfeste Gussteile, refraktärer Mörtel, usw., and realize high-quality and efficient production of feuerfeste Materialien.

Professional Engineer Service

We have a team of experienced engineers who can provide customers with professional refractory solutions to ensure the best use of the products.

Strong refractory factory supply capacity

Rongsheng Refractory has two refractory factories. Rongsheng is able to supply a large number of monomer refractory products stably. More importantly, it has exported refractory materials to more than 50 countries and has rich export experience.

High-quality refractory products

Rongsheng will strictly control product quality, which provides customers with high-quality product assurance. Gleichzeitig, we can customize refractory materials for customers.

Rongsheng Refractories Factory

Rongsheng Refractories Factory

FÜR 50 KILOS TASCHE REFRACTARY CASTLE WIE VIELE LITER WASSER BRAUCHEN WIR+584121968090

OK,Wir werden uns so schnell wie möglich mit Ihnen in Verbindung setzen