Proces výroby žáruvzdorných koulí s vysokým obsahem hliníku Úvod

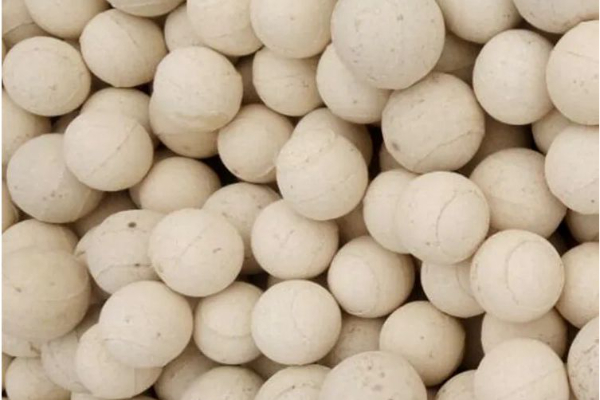

High-aluminum refractory balls are also called spherical regenerators. Spherical regenerators have the characteristics of good thermal shock stability, large heat storage, and high strength. Suitable for the selection of regenerative ball combustion systems for gas and non-gas fuel industrial furnaces. Aluminosilicate refractory materials with an Al2O3 content greater than 48% are collectively called high-aluminum refractory materials. The following is an introduction to the production process of high-aluminum heat storage balls.

The production process of high aluminum refractory balls

1. Selection and grading of alumina clinker

First, select raw materials that meet the requirements. High-aluminum clinker is the main raw material for the production of high-aluminum refractory balls. Bauxite clinker needs to be strictly graded and selected to avoid mixing with mixed impurities. According to the quality requirements of different grades of high aluminum refractory balls, different grades of raw materials are selected.

2. Finely grind the clinker and bonded clay together

Part of the alumina clinker is mixed and finely ground with binding clay, which can improve the quality of the refractory ball product, control the secondary mulliteization reaction in the matrix, and eliminate or weaken the secondary mulliteization effect on the surface of the clinker particles. The effect is remarkable.

3. Firing temperature

The firing temperature of high alumina refractory balls mainly depends on the sintering characteristics of the alumina clinker. When using special grade alumina clinker, due to the uniform and dense structure of the raw material and the high content of impurities Fe2O3 and TiO2, the green body is easy to sinter, and the sintering temperature range is narrow, which easily causes over- or under-burning. Proto, secondary alum is used. When clay clinker is used, due to the expansion and loosening effects caused by secondary multimerization, the green body is not easy to sinter, so the firing temperature needs to be relatively high. High alumina refractory balls can be fired at the same temperature, which is 1450°C when fired in an inverted flame kiln.

High aluminum refractory ball production process precautions

- Conduct an on-site inspection of the raw materials for the production of refractory balls, and the samples will be tested for trial burning and physical and chemical indicators. The test results can only be used after they meet the user’s requirements. The purchased raw materials will be strictly inspected and processed into 0-3 particle size and 180 mesh. The powder is removed by a 16000-high magnetic iron remover and then enters the silo for use.

- Mold making is carried out in the mold workshop, and the dimensions of the semi-finished products must be checked. Only after they are confirmed to be correct can they be heated.

- In the molding workshop, the particle size and fineness of the raw materials are randomly inspected using a sample sieve. After passing the test, the raw materials are proportioned through the electronic batching truck and then entered into the mixing mill for mixing. The trapped material will be out of the pot in 10-15 minutes, starting in 2-4 hodin. During molding, the number of single hammers and the body density of the semi-finished product are checked. Mass production can only be carried out after confirmation.

The semi-finished products produced must have consistent unit weight, hladký povrch, no burrs, and no brown eyes before they can be loaded into the kiln in the next process. - In the firing workshop, the semi-finished refractory balls entering the kiln must be inspected for size burrs and brown eyes. Only after the inspection is correct can they be installed in the kiln. When installing the kiln, they must be handled with care and placed reasonably and neatly.

- After leaving the kiln, the finished refractory balls are inspected for size and appearance. Ready for shipment once correct.

Továrna na žáruvzdorné materiály Rongsheng

Továrna na žáruvzdorné materiály Rongsheng

WeChat

Naskenujte QR kód pomocí wechat