What are the characteristics of magnesia-calcium refractory bricks?

Magnesia-calcium refractory bricks are refractory materials with MgO and CaO as the main components and are alkaline refractory materials. The following is a description of the characteristics of magnesia-calcium bricks.

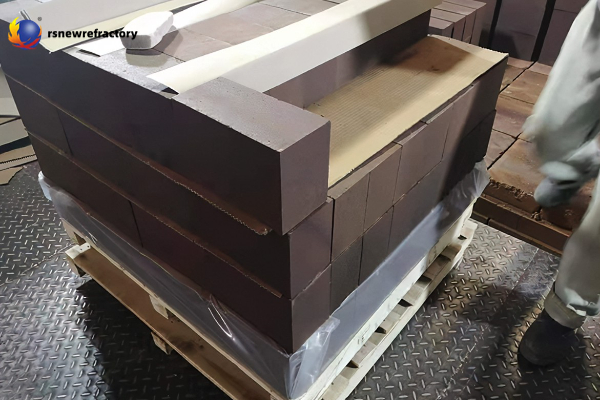

Magnesia-calcium refractory bricks characteristics

(1) High temperature resistance

The main components MgO and CaO are both high melting point (2800℃ and 2570℃ respectively) oxides, and the eutectic temperature of the two is also above 2300℃. This type of material has good high-temperature resistance.

(2) Slag resistance

Magnesium calcium bricks have good slag resistance, especially with the increase of slag basicity, the slag erosion decreases rapidly, and the slag intruding into the brick reacts with CaO in the brick to form C2S and C3S, making the slag viscosity higher and the wetting angle larger, which hinders the slag from penetrating into the brick and prevents the formation of a thick colloid layer. For low-basicity slag, CaO in magnesium-calcium sand dissolves first, making the slag more basic and viscous and more difficult to dissolve. Magnesium-calcium sand particles can improve slag resistance.

(3) Thermal shock resistance

Magnesium calcium bricks contain more free CaO. At high temperatures, they have large creep and good plasticity. They can buffer the thermal stress caused by temperature fluctuations. They have good thermal shock resistance and are suitable for working environments with drastic temperature changes in off-furnace refining.

(4) Stability under high temperature and vacuum

High-purity magnesia dolomite bricks are very stable under high-temperature vacuum and have a very small weight loss rate. This is obviously superior to magnesia-chrome bricks and is more suitable for use in out-of-furnace refining with high-temperature vacuum working environments.

(5) Purify molten steel

Magnesia-calcium-based materials contain a lot of free Ca O, which easily reacts with inclusions such as [S] and [P] in the molten steel, causing them to migrate into the slag and have the function of removing impurities and purifying the molten steel. This is a remarkable characteristic that cannot be compared with other refractory materials. It is the first choice and best refractory material in clean steel and special steel refining.

(6) Ease of hydration

When calcium oxide meets water or moisture, it will generate calcium hydroxide Ca0+H20-→Ca(OH)2, H=+65.63kJ/mol

This is a spontaneous reaction, and the reaction is inevitable as long as it encounters water or moisture. Due to the hydration of Ca O, Ca(OH)2 expands in the [001] direction, causing the magnesia-calcium sand to pulverize, causing cracks or cracks in the bricks.

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Scan the QR Code with wechat