Magnesia chrome brick is a refractory brick with magnesium oxide and chromium oxide as the main components, and the main mineral components are periclase and spinel. Fired at 1600~1800°C in an oxidizing atmosphere, it can also be made into unfired bricks with chemical binders such as water glass. Magnesia-chrome bricks have high refractoriness, strong corrosion resistance to alkaline slag, good thermal stability, and a certain resistance to acid slag.

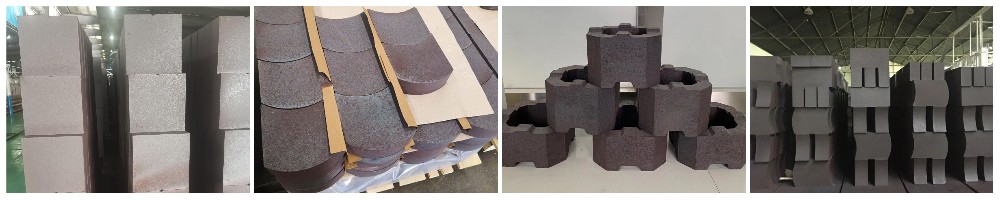

Production and manufacture of magnesia chrome bricks

The main raw materials of magnesia chrome bricks are sintered magnesia and chromite. In the process of producing magnesia chrome bricks, the purity of magnesia raw materials should be high. The chemical composition standard of chrome ore is 30%-45% of Cr2о3, ≤ 1-1.5% Цао.

Composition of magnesia chrome brick

- Ordinary sintered magnesia-chrome bricks: The purity of raw materials is not high, lightly burned magnesia is used, and the sintering temperature is low.

- Directly bonded magnesia-chrome bricks: The raw materials are of high purity, using dead-burned magnesia, and the sintering temperature of the bricks in the tunnel kiln is higher than that of ordinary sintered magnesia-chrome bricks.

- Fused semi-recombined magnesia-chrome bricks: The raw materials are dead-burned magnesia and fused magnesia, and the sintering temperature is higher than that of ordinary sintered magnesia-chrome bricks.

- Fused and recombined magnesia-chrome bricks: The raw material is made of fused magnesia, and the cost is high.

Physical and chemical indicators of magnesia chrome bricks

Physical and chemical indicators ofOrdinary Magnesia Chrome Brick:

| Пункт | Паказальнік | |||||

| MG-16A | MG-16B | MG-12A | MG-12B | MG-8A | MG-8B | |

| MgO % | ≥50 | ≥45 | ≥60 | ≥55 | ≥65 | ≥60 |

| кр2О3 % | ≥16 | ≥16 | ≥12 | ≥12 | ≥8 | ≥8 |

| Бачная сітаватасць % | ≤19 | ≤22 | ≤19 | ≤21 | ≤19 | ≤21 |

| Трываласць пры халодным раздушванні МПа | ≥35 | ≥25 | ≥35 | ≥30 | ≥35 | ≥30 |

| 0.2Рэфрактыўнасць MPA пры нагрузцы ℃ | ≥1650 | ≥1550 | ≥1650 | ≥1550 | ≥1650 | ≥1530 |

Physical and chemical indicators ofFused Semi-Recombined Magnesia Chrome Brick:

| Пункт | Паказальнік | |||

| ZMG-16A | ZMG-12A | ZMG-8A | ZMG-6 | |

| MgO % | ≥60 | ≥68 | ≥75 | ≥75 |

| кр2О3 % | ≥16 | ≥12 | ≥8 | ≥6 |

| Сіё2 % | ≤1,5 | ≤1,5 | ≤1,5 | ≤2.5 |

| Бачная сітаватасць % | ≤18 | ≤18 | ≤18 | ≤18 |

| Трываласць пры халодным раздушванні МПа | ≥40 | ≥45 | ≥45 | ≥45 |

| 0.2Mpa Refractoriness Under Load℃ | ≥1700 | |||

Physical and chemical indicators of Fused Semi-Recombined Magnesia Chrome Brick :

| Пункт | Паказальнік | |||

| BMG-26 | BMG-24 | BMG-22 | BMG-20A | |

| MgO % | ≥50 | ≥50 | ≥55 | ≥58 |

| кр2О3 % | ≥26 | ≥24 | ≥22 | ≥20 |

| Сіё2 % | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 |

| Бачная сітаватасць % | ≤16 | ≤16 | ≤16 | ≤16 |

| Трываласць пры халодным раздушванні МПа | ≥40 | ≥45 | ≥45 | ≥45 |

| 0.2Mpa Refractoriness Under Load℃ | ≥1700 | |||

| Пункт | Паказальнік | ||

| BMG-18 | BMG-16A | BMG-12A | |

| MgO % | ≥58 | ≥60 | ≥68 |

| Cr2O3 % | ≥18 | ≥16 | ≥12 |

| SiO2 % | ≤2.0 | ≤2.0 | ≤2.0 |

| Бачная сітаватасць % | ≤16 | ≤16 | ≤16 |

| Трываласць пры халодным раздушванні МПа | ≥40 | ≥45 | ≥45 |

| 0.2Mpa Refractoriness Under Load℃ | ≥1700 | ||

Physical and chemical indicators ofFused Recombined Magnesia Chrome Brick:

| Пункт | Паказальнік | |||||

| DMG-26 | DMG-24 | DMG-22 | DMG-20 | DMG-16 | DMG-12 | |

| MgO % | ≥50 | ≥50 | ≥55 | ≥58 | ≥62 | ≥68 |

| кр2О3 % | ≥26 | ≥24 | ≥22 | ≥20 | ≥16 | ≥12 |

| Сіё2 % | ≤1,5 | ≤1,5 | ≤1,5 | ≤1,5 | ≤1,5 | ≤1,5 |

| Бачная сітаватасць % | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 |

| Трываласць пры халодным раздушванні МПа | ≥40 | ≥40 | ≥40 | ≥40 | ≥40 | ≥40 |

| 0.2Mpa Refractoriness Under Load℃ | ≥1700 | ≥1700 | ≥1700 | ≥1700 | ≥1700 | ≥1700 |

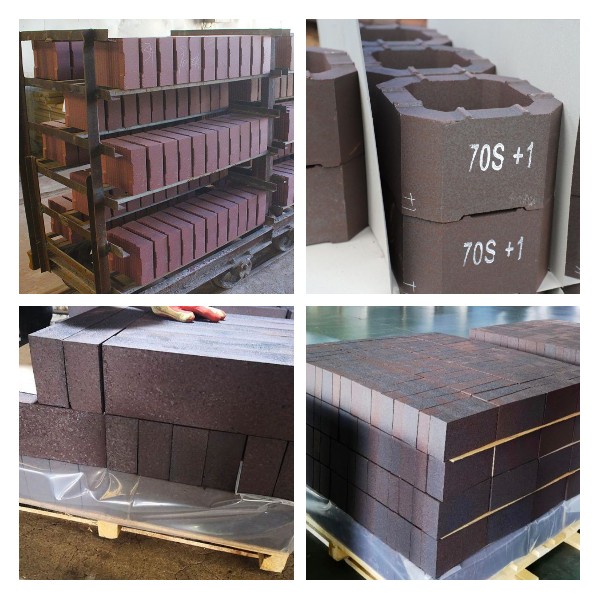

Features of magnesia chrome brick

- High purity and low impurity

- High temperature and mild

- Strong corrosion resistance

- Low porosity

- Доўгі тэрмін службы

- Not easy to wear

- Production meets the standard

The temperature range of magnesia chrome brick

The refractoriness of magnesia chrome bricks is greater than 2000°C, and the load softening temperature is generally above 1550°C. It has good volume stability at high temperatures and good resistance to rapid cooling and heat.

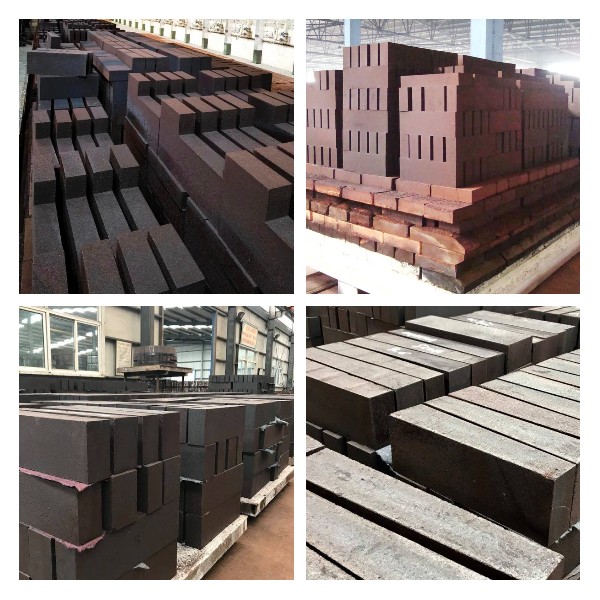

Application field of magnesia chrome brick

Magnesia-chrome bricks can be mainly used in cement rotary kilns, glass kiln regenerators, steelmaking furnace lining, a permanent layer of refining ladles, nonferrous metallurgical furnaces, lime kilns, mixed iron furnaces, and refractory high-temperature furnace lining, г.д.

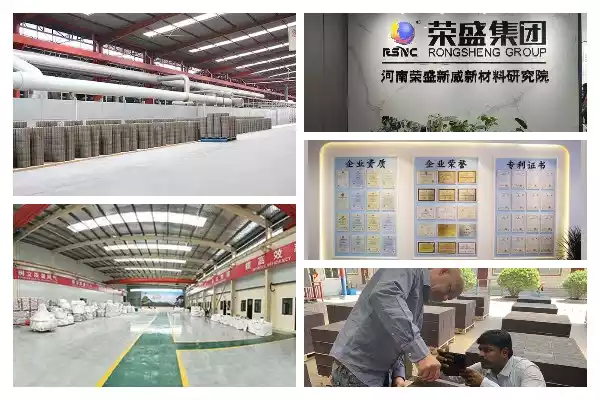

Пастаўшчык вогнетрывалых матэрыялаў Rongsheng

Фабрыка вогнеўпораў Rongsheng

Фабрыка вогнеўпораў Rongsheng

WeChat

Адсканіруйце QR-код з дапамогай wechat