Сардэчна запрашаем у Rongsheng Refractories! Як вядучы сусветны пастаўшчык вытворцаў вогнетрывалых матэрыялаў, мы імкнемся забяспечыць высокую якасць вогнетрывалыя вырабы і прафесійныя вогнетрывалыя тэхнічныя паслугі для ўсіх слаёў грамадства. Мы можам забяспечыць найбольш прыдатныя вогнетрывалыя рашэнні для сталі, шкло, кераміка, цэмент, нафтахімічны, магутнасць, або іншыя высокатэмпературныя галіны.

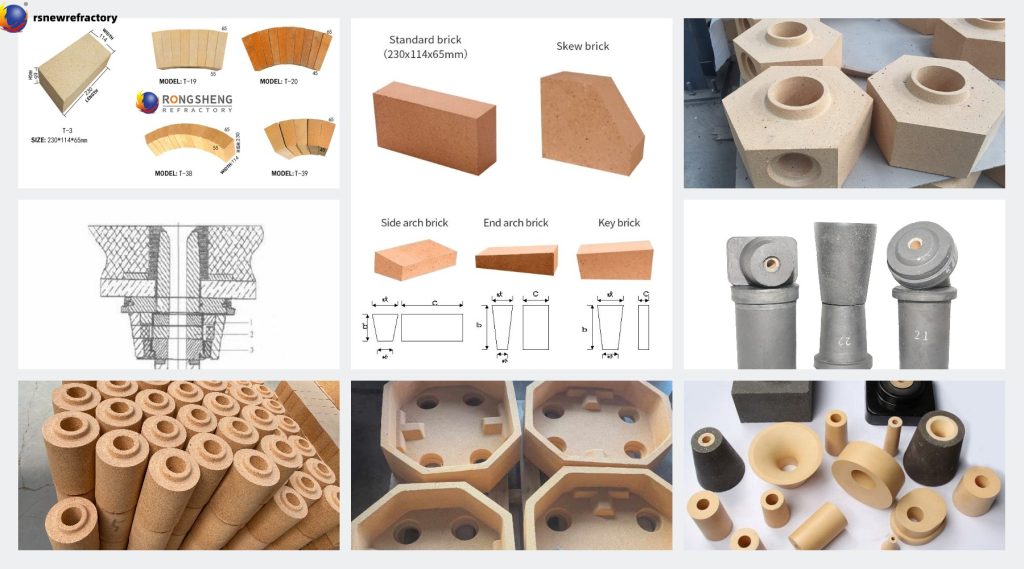

Вогнетрывалыя вырабы на ваш выбар

Высокотэмпературная вогнетрывалая цэгла

У нас ёсць сотні розных відаў вогнетрывалай цэглы, з якіх вы можаце выбраць. Мы таксама можам парэкамендаваць прыдатныя высокатэмпературныя вогнетрывалыя цэглы ў залежнасці ад тэмпературы вашай печы і працоўнага асяроддзя. Ніжэй прыведзены некалькі папулярных вогнетрывалых цэглы.

Цэгла з высокім утрыманнем гліназёму

Высокая вогнетрывалая тэмпература

Добрая трываласць

Ўстойлівасць да хімічнай карозіі

Добрая цеплаправоднасць

Доўгі тэрмін службы

Зносаўстойлівы

| Фізіка-хімічны індэкс вогнетрывалай цэглы з высокім утрыманнем алюмінію: | ||||||

| Пункт | Уласцівасці | |||||

| РС-80 | РС-75 | РС-65 | РС-55 | РС-48 | ||

| Al2O3(%) | 80 | ≥75 | ≥65 | ≥55 | ≥48 | |

| Тугаплаўкасць(°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1770 | ≥1750 | |

| Насыпная шчыльнасць(г/см3) | 2.65 | 2.5 | 2.45 | 2.4 | 2.3 | |

| Тэмпература размякчэння пад нагрузкай(°C ) | 1530 | ≥1520 | ≥1500 | ≥1470 | ≥1420 | |

| Перагрэў Лінейныя змены хуткасці (%) | 1500°CX2H | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 1450°CX2H | -0.4 | -0.4 | -0.4 | -0.4 | -0.4 | |

| Ўяўная сітаватасць (%) | 22 | ≤23 | ≤23 | ≤22 | ≤22 | |

| Трываласць на халоднае раздушванне (Мпа) | 55 | ≥50 | ≥45 | ≥40 | ≥35 | |

| Ужыванне | сталёвая печ, шкловарная печ, печ з сілікатам натрыю, керамічная печ-чаўнок, печ для абпалу цэменту, домна, электрычная печ, домна і рэверберацыйная печ. | |||||

Магнезіальна-вугляродная цэгла

- Добрая ўстойлівасць да высокіх тэмператур.

- Моцная шлакостойкость.

- Добрая ўстойлівасць да тэрмічнага ўдару.

- Нізкая паўзучасць пры высокіх тэмпературах.

- Нізкі каэфіцыент цеплавога пашырэння, нялёгка дэфармаваць.

- Нялёгка ачысціць.

| Вугляродная цэгла Magneisa | ||||||

| Пункт/Індэкс | МГЦ-10 | МГЦ-12 | МГЦ-15 | МГЦ-18 | МГЦ-20 | |

| Аб'ёмная шчыльнасць (г/см3) | 2.95 | 2.90 | 2.85 | 2.80 | 2.78 | |

| Уяўная сітаватасць (%) | 3~5 | 3~5 | 3~5 | 3~5 | 3~5 | |

| Трываласць на сціск (кг/см2) | 450 | 400 | 400 | 350 | 350 | |

| Пашырэнне ст 1000 ℃ | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | |

| Хімічны склад (%) | MgO | 86 | 84 | 80 | 76 | 74 |

| Ф.К. | 10 | 12 | 15 | 18 | 20 | |

| Ужыванне | Коўшык | EAFLаdle | БОФЕФАКоўшык | БОФЕФЛФ | БОФЕАФ | |

AZS Брык

1. Ўстойлівасць да высокіх тэмператур, высокая трываласць, шырока выкарыстоўваецца ў розных печах

2. Сыравіна з высокай чысцінёй і высокім утрыманнем алюмінія

3. Нізкая цеплаправоднасць. Добрая тэрмічная стабільнасць і ўстойлівасць да карозіі

4. Памер дакладны і можа быць настроены.

| Пункт | Плаўленая літая цэгла AZS | |||

| Паказальнік | RS-AZS33 | RS-AZS36 | RS-AZS41 | |

| Хімічны склад % | Al2O3 | ≥50,00 | ≥49,00 | ≥45,00 |

| ZrO2 | ≥32,50 | ≥35,50 | ≥40,50 | |

| SiO2 | ≤15.00 | ≤13,50 | ≤12,50 | |

| Na2O+K2O | ≤1,30 | ≤1,35 | ≤1,30 | |

| Аб'ёмная шчыльнасць г/см3 | ≥3,75 | ≥3,85 | ≥4,00 | |

| Бачная сітаватасць % | ≤1,2 | ≤1,0 | ≤1,2 | |

| Трываласць на халоднае раздушванне, МПа | ≥200 | ≥200 | ≥200 | |

| Тэмпература эксудацыі шкляной фазы | ≥1400 | ≥1400 | ≥1410 | |

| Каэфіцыент аддзялення бурбалак(1300 ℃ × 10 гадзін) | ≤1,2 | ≤1,0 | ≤1,0 | |

| Хуткасць антыкаразійнай стойкасці шкляной вадкасці 1500 ℃ × 36 гадзін (мм/24 гадзіны)% | ≤1,4 | ≤1,3 | ≤1,2 | |

| Насыпная шчыльнасць(г/см3) | Радавы ліццё PT(РН РК Н) | ≥3,55 | ≥3,55 | ≥3,70 |

| Без ўсаджвання ліцця ZWS(RR EVF EC ENC) | ≥3,65 | ≥3,75 | ≥3,85 | |

| Нахіленае ліццё QX(RO) | ≥3,65 | ≥3,75 | ≥3,90 | |

| Ліццё без ўсаджвання WS( RT VF EPIC FVP DCL) | ≥3,75 | ≥3,80 | ≥3,95 | |

Карбід крэмнія мулітавыя цэгла

Ўстойлівасць да карозіі

Ўстойлівасць да ізаляцыі

Ўстойлівасць да тэрмічнага ўдару

Добрая цеплаправоднасць

| Пункт | GM1650 | GM1600 | GM1550 | GM1680 |

| Al2O3 % | 63 | 60 | 57 | 63 |

| SiO2+SiC % | 30 | 30 | 30 | 30 |

| Ўяўная сітаватасць % | 17 | 17 | 19 | 17 |

| Трываласць пры халодным раздушванні Мпа | 85 | 90 | 90 | 100 |

| Вогнеўстойлівасць пад нагрузкай ℃ (0.2Мпа) | 1650 | 1600 | 1550 | 1680 |

| Ўстойлівасць да тэрмічнага ўдару(11оо℃, вадзяное астуджэнне) | 10 | 10 | 12 | 13 |

| Насыпная шчыльнасць г/см3 | 2.65 | 2.60 | 2.55 | 2.65 |

| Устойлівасць да халоднага ізаляцыі см3 | 5 | 5 | 5 | 5 |

| Цеплаправоднасць(ж/м·к) | 1.7 | 1.7 | 1.7 | 1.7 |

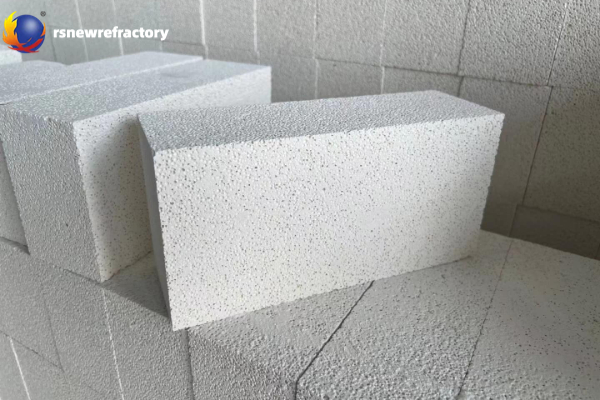

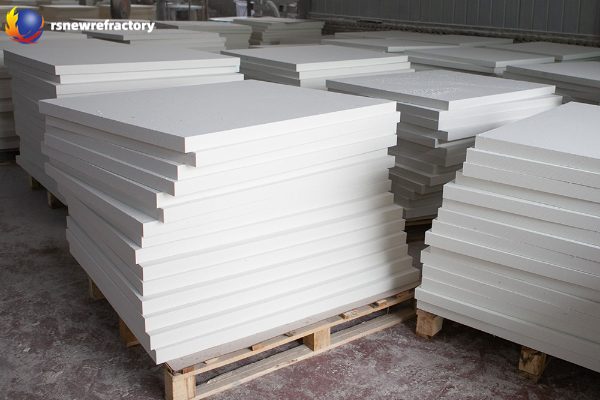

Ізаляцыйныя цэглу

Муллитовая ізаляцыйная цэгла

- Плаўленне з нізкай тэмпературай

- Нізкая цеплаправоднасць

- Высокая вогнеўстойлівасць

- Добрая хімічная ўстойлівасць

- Высокая трываласць на сціск і выгіб

- Дакладны выгляд і памер

| Муллитовая ізаляцыйная цэгла | ||||||

| Пункт/Індэкс | RS23 | RS26 | RS28 | RS30 | RS32 | |

| Al2O3 % | 37 | 54 | 64 | 72 | 77 | |

| Fe2O3 % | 1.0 | 0.9 | 0.8 | 0.7 | 0.5 | |

| Цеплаправоднасць (ш/м*к) | 400℃ | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

| 600℃ | 0.16 | 0.29 | 0.34 | 0.43 | 0.5 | |

| 800℃ | 0.18 | 0.31 | 0.36 | 0.44 | 0.51 | |

| 1000℃ | 0.20 | 0.33 | 0.38 | 0.45 | 0.53 | |

| Класіфікацыя Тэмпература (℃) | 1260 | 1430 | 1540 | 1650 | 1760 | |

| Цеплавое пашырэнне 1000 ℃ (%) | 0.5 | 0.7 | 0.8 | 0.9 | 1.1 | |

| Аб'ёмная шчыльнасць (г/см3) | 0.55-0.62 | 0.78-0.8 | 0.88 | 1.03 | 1.25 | |

| Трываласць на халоднае раздушванне (Мпа) | 1.2 | 1.6 | 2.1 | 2.5 | 3.5 | |

| Модуль разрыву (Мпа) | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

| Лінейнае змяненне разагрэву (%)CT-30℃*8H | 1230℃-0.5 | 1400℃-0.5 | 1510℃-0.5 | 1620℃-0.9 | 1730℃-0.9 | |

Маналітнае вогнетрывалае выраб

Маналітныя вогнетрывалыя матэрыялы, таксама вядомы як сыпкія вогнетрывалыя матэрыялы або аморфныя вогнетрывалыя матэрыялы, адносяцца да тых вогнетрывалым матэрыялах, якія не ўтвараюцца пры абпале. У адрозненне ад традыцыйнага фасоннага вогнетрывалай цэглы, бесструктурныя вогнетрывалыя матэрыялы не маюць фіксаванай формы або памеру. Звычайна яны існуюць у выглядзе парашка, гранулы, гразь, або валакна. Пры выкарыстанні, яны непасрэдна наліваюцца, ўтрамбаваны, апырскваюць, прыкладной, або запаўняецца на будаўнічай пляцоўцы ў адпаведнасці з патрэбамі.

Нізкія і звышнізкія цэментныя канструкцыі

- Высокая вогнеўстойлівасць, высокая тэмпература, і ўстойлівасць да нізкіх тэмператур

- Устойлівасць да эрозіі, ўдаратрываласць, высокая зносаўстойлівасць, высокая трываласць

- Моцная пластычнасць, можна адліць у любую форму

- Добрая паветранепранікальнасць, можа паменшыць страты цяпла і зэканоміць энергію

| м | Ультранізкі цэмент | |||

| Матэрыял | Гліна | Высокі гліназём | Карунд | |

| Аб'ёмная шчыльнасць (г/см3) | 2.35 | 2.70 | 3.20 | |

| Al2o3(%) | 45 | 75 | 95 | |

| Цао(%) | 1.15 | 1.15 | 1.15 | |

| Трываласць на выгіб(Мпа) | 110℃*16 гадзін | 6 | 6 | 8 |

| 1500℃*3h | 8 | 8 | 10 | |

| Трываласць на сціск(Мпа) | 110℃*16 гадзін | 40 | 40 | 60 |

| 1500℃*3h | 70 | 800 | 90 | |

| Хуткасць змены лініі пасля запісу(%) | 110℃*16 гадзін | -0.1 | 0 | 0 |

| 1500℃*3h | +-0.5 | +-0.5 | +-0.5 | |

| Тугаплаўкасць | ℃ | 1710 | 1790 | 1790 |

| Тэмпература бяспечнага абслугоўвання | ℃ | 1400 | 1450 | 1650 |

Вырабы з керамічнага валакна

Індывідуальныя іншыя віды вогнетрывалых вырабаў

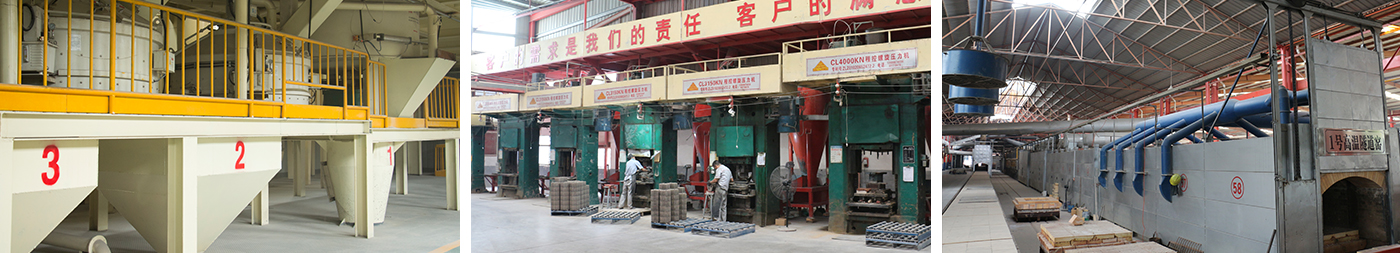

Вытворчасць вогнетрывалых вырабаў

Вытворцы вогнетрывалых матэрыялаў’ справы кліентаў

Пасля 20 гадоў назапашвання, у нас шмат паспяховых кліентаў, якія ахопліваюць розныя галіны і краіны. Напрыклад, мы пастаўляем цэглу з высокім утрыманнем гліназёму для металургічных заводаў, наладзіць цэглу з цыркону, устойлівую да высокіх тэмператур, для шкляных заводаў, і забяспечваюць розныя вогнетрывалыя вырабы для ліцейных заводаў. Нашы прадукты атрымалі высокую ацэнку і давер кліентаў.

Фабрыка вогнеўпораў Rongsheng

Фабрыка вогнеўпораў Rongsheng

Шукаю каменныя цэглы

4. X 9. X. 1 1/4

7807140474

Дзякуй за ваш запыт. Наша служба продажаў звяжацца з вамі, каб абмеркаваць ваш праект.