مقدمة الفرن الكهربائي الجرافيت

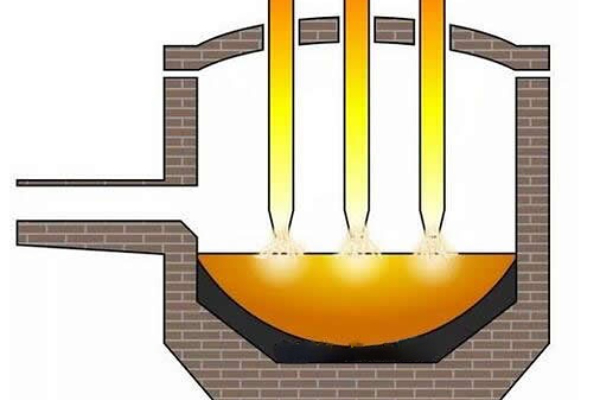

Furnace graphite electrode is an important electrode material widely used in high-temperature electric furnaces in metallurgy, صناعة كيميائية, الطاقة الكهربائية, وغيرها من المجالات الصناعية, mainly for smelting metals and generating high-temperature reactions.

The manufacturing process of furnace graphite electrode

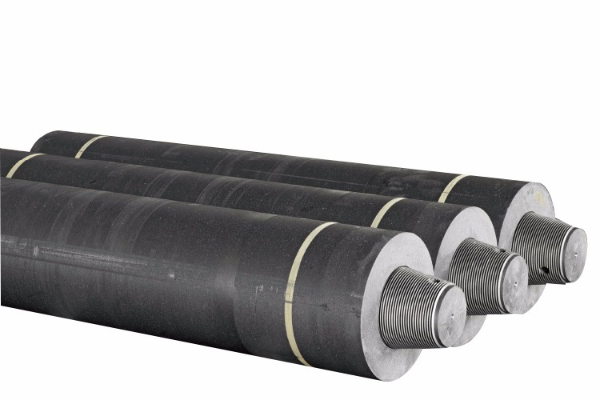

Graphite electrodes are made of natural graphite as the main raw material through processing, baking, and graphitization. It has the advantages of high electrical conductivity, high-temperature stability, chemical stability, والقوة الميكانيكية, and is suitable for high-temperature and high-pressure environments.

The process of manufacturing graphite electrodes includes mixing raw materials, صب, baking, graphitization, إلخ. في نفس الوقت, the difference in the manufacturing process will affect the physical properties and service life of the electrode.

Graphite electrodes application

Graphite electrodes are mainly used in high-temperature smelting equipment such as electric arc furnaces and induction furnaces to smelt steel, alloys, non-ferrous metals, and other ores, as well as electrochemical processes such as electrolytic aluminum and electrolytic copper.

Classification of graphite electrodes

Graphite electrodes can be divided into different types according to their use and size, such as ultra-high power graphite electrodes, high power graphite electrodes, normal power graphite electrodes, إلخ. They differ in terms of electrical conductivity, مقاومة درجات الحرارة العالية, and service life.

Furnace graphite electrode working principle

The principle of graphite electrode is to use the arc between the end of the electrode and the steel material in the furnace to generate high temperature as a heat source to melt the furnace material for steelmaking; similarly, it can also be used to smelt various other metal raw materials.

مصنع رونغ شنغ للحراريات

مصنع رونغ شنغ للحراريات

WeChat

امسح رمز الاستجابة السريعة باستخدام wechat