تأثير محتوى الجرافيت في الطوب mgo c

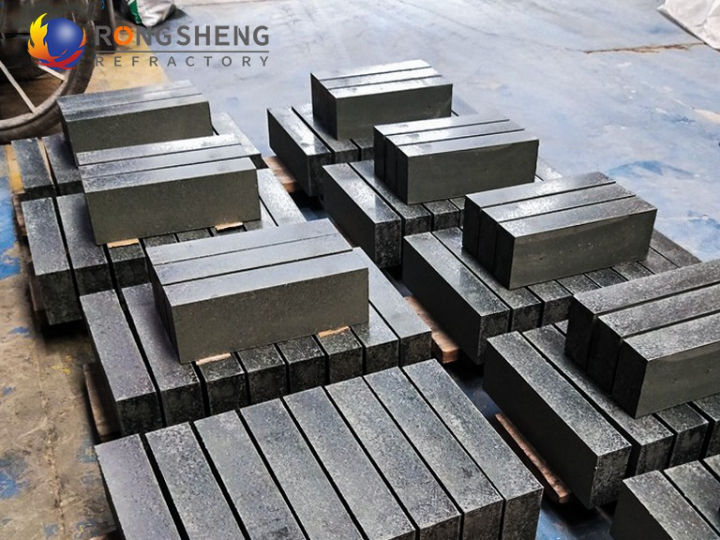

Mgo c bricks are widely used in modern iron and steel metallurgical industry, such as linings of various electric arc furnaces, مغارف, and steelmaking refining furnaces (BOF, RH). طوب الكربون المغنيسيا are alkaline refractory materials made of magnesia sand and graphite using various binders. As an important component of magnesium carbon refractory materials, graphite content has a crucial influence on the performance of magnesium carbon refractory materials.

The role of graphite in magnesium carbon bricks

Due to the high thermal conductivity, low thermal expansion coefficient and non-wetting between graphite and slag, the addition of graphite greatly improves the thermal shock resistance and slag erosion resistance of magnesium carbon refractory materials.

لكن, graphite is easily oxidized, which increases the porosity of magnesium carbon bricks to a certain extent, and also leads to reduced strength and erosion resistance, as well as material peeling and structural damage. لذلك, studying the oxidation resistance of magnesium carbon refractory materials has very important practical significance.

Effect of graphite content on mgo c bricks

(1) The bulk density of the MgO-C brick sample decreases with the increase of graphite content, while the porosity increases with the increase of graphite content. After carbonization at 900℃, the bulk density of the MgO-C brick sample decreases, while the porosity increases significantly.

(2) The higher the graphite content in the MgO-C brick sample, the thinner the decarburization layer thickness and the lower the graphite oxidation rate. في نفس الوقت, the decarburization layer thickness and graphite oxidation rate of the MgO-C brick sample oxidized at 1400℃ are lower than those of the MgO-C brick sample oxidized at 1000℃.

(3) The oxidation rate of the MgC brick sample calculated by the oxidation model is consistent with the changing trend of the graphite content and the actual measured decarburization layer thickness. That is, the oxidation rate decreases with the increase of graphite content, and the decrease is most obvious when the graphite content is low.

مصنع رونغ شنغ للحراريات

مصنع رونغ شنغ للحراريات

WeChat

امسح رمز الاستجابة السريعة باستخدام wechat