What are the application fields of silica bricks?

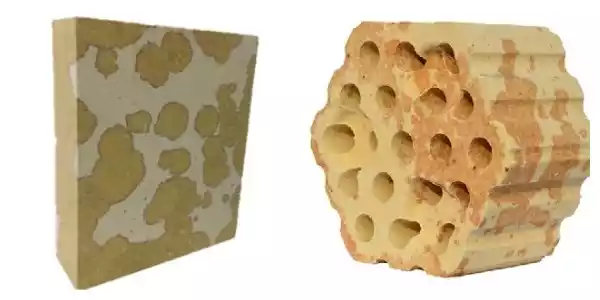

Silica bricks is a refractory product with a SiO2 content of more than 92%. The higher the SiO2 content in the silica raw material, the higher the refractoriness of the product; the silica refractory bricks have a strong ability to resist acid erosion, and correspondingly.

Application of silica bricks

Glass industry

Silica bricks are mainly used in masonry roofs, parapets, hanging walls, and flow channels of glass-melting furnaces. According to the temperature of the high-temperature gas in the glass, furnace is as high as 1615 ° C, the silica refractory bricks on the roof must withstand gravity, mechanical stress, and high temperature. Therefore, it needs to have good high-temperature mechanical properties; the volume stability at high temperatures is good, and the volume of the product cannot change during use, otherwise, it will cause deformation, damage, or even collapse of the furnace.

The high-temperature resistance of silica bricks; lightweight High strength meet the requirements of glass furnaces, so it is widely used in glass furnaces.

Iron industry

In the iron and steel industry, silica bricks are widely used as refractory linings in high-temperature areas such as blast furnaces, converters, electric arc furnaces, and continuous casting equipment. It can withstand extremely high temperatures and chemical attacks, protecting equipment from molten metal and slag.

Petrochemical industry

Silica refractory bricks also have critical applications in the petrochemical industry. It is used as a refractory lining for cracking furnaces, and catalytic and refining units. The high-temperature stability and acid and alkali corrosion resistance of silica bricks enable them to operate stably for a long time in harsh petrochemical process environments.

Classification of silica bricks

There are many varieties of silica bricks, which can be divided into: silica bricks for coke ovens, silica bricks for hot blast furnaces, silica bricks for electric furnaces, silica bricks for glass kilns, etc.

According to the complexity of the brick type, it can be divided into standard brick, general brick, special brick, and special brick.

Precautions for the use of silica brick

(1) Due to the change of the crystal form of the remaining quartz at low temperatures, the volume of silicon products changes greatly, so the temperature rise below 600°C is not too fast when the oven is baked, and it should be cooled slowly to 600°C to avoid cracks.

(2) Avoid contact with basic slag as much as possible.

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Scan the QR Code with wechat